Advantages of certified, used construction machinery:

This text about used machinery certification is available in German language.

Quality assurance: Certified used machines usually undergo a thorough inspection and maintenance by the manufacturer or an authorised dealer. This ensures that the machine is in good condition and meets the technical standards.

Guarantee: Manufacturers often offer a guarantee or warranty on certified used machines. This minimises the risk for the buyer and offers additional security in the event of any problems.

Transparency: Buyers often receive detailed documentation of the inspections and maintenance work carried out. This makes the condition of the machine transparent and traceable.

Reliability: As the machines have been inspected and serviced by the manufacturer, they are usually more reliable than non-certified used machines, which may not have undergone the same inspection process.

Financing options: Some manufacturers offer special financing terms for certified pre-owned machines, which can make the purchase more attractive.

Stable value: Certified pre-owned machines often have a higher resale value as they have been officially inspected and serviced, which increases confidence in their quality.

We are ready to send engineers for on-site inspections to most areas of the world. Our team speaks several languages and we are used to working on construction sites, in quarries or open pit mines. For more information, just give us a call.

In-house certification or use an external organisation?

A provider who outsources the certification of used machinery to an external assessor can benefit from several advantages:

Credibility and independence: certification by an external assessor increases the credibility of the assessment, as it is carried out by an independent and neutral body. This strengthens customer confidence in the quality and reliability of the certified machines.

Risk minimisation: Outsourcing certification reduces the risk associated with possible quality defects or incorrect assessments. The supplier can rely on the external assessor to carry out an objective and professional assessment.

Specialisation and expertise: External valuers often have specialised knowledge and many years of experience in the valuation of construction machinery. This expertise can lead to a more accurate and comprehensive assessment than would possibly be possible internally.

Cost efficiency: Outsourcing certification can be more cost efficient for the provider as they do not need to allocate internal resources to train and employ their own assessors. Instead, the costs can be kept variable, depending on the requirements and scope of the certifications.

Time savings: An external assessor can often act more quickly as they focus solely on certification and have no other operational tasks. This can speed up the certification process and shorten the time to market for used machinery.

By outsourcing certification, a supplier can thus strengthen its own credibility and optimise its costs.

Who can certify used machinery?

The certification of used construction machinery could be outsourced to TÜV, Intertek or SGS, for example. This would have the advantage that the inspectors are available nationwide. The disadvantage is that TÜV and SGS are not specialised in construction machinery, but deal with all kinds of industries and especially cars and trucks. Certification with a service provider such as Mevas Baumaschinen-Gutachten would have the advantage that the service is also offered nationwide, is certainly cheaper and faster than by TÜV and the company specialises in the analysis of construction machinery.

Which machines does Mevas test and certify and where?

We test almost all machines and lifting equipment used on construction sites or in the construction industry. Various inspectors and experts are deployed in various countries. Get in touch with us to learn if we can support the used machinery business in your country.

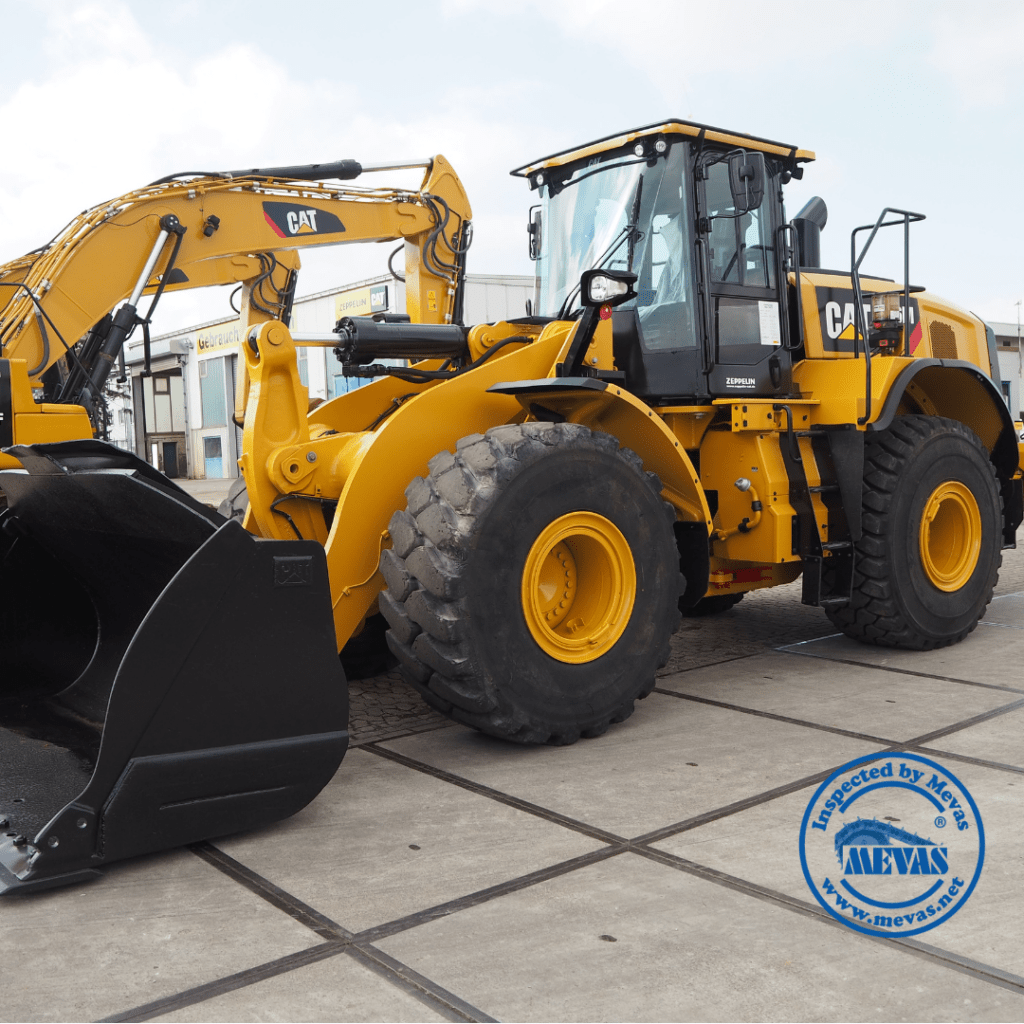

- Earth-moving machinery, excavators, wheel loaders, bulldozers

- Mobile cranes and lifting gear

- Aerial work platforms, telescopic work platforms

- Telehandlers, material handlers

Which tests and documentation should be carried out for the certification of a used construction machine?

The certification of a used construction machine should include a comprehensive inspection and documentation to ensure that the machine fulfils the requirements for safety, functionality and performance. Here are the essential tests and documentation that should be included:

1. visual inspection:

- General condition: check for visible damage, corrosion, wear or missing parts.

- Structure and frame: Check for cracks, deformation or other structural problems.

- Paintwork: Assessment of the condition of the paintwork to identify any repainting or damage.

2. functional tests:

- Engine test: checking the engine for power, smoke, unusual noises and leaks.

- Hydraulic system: Test the hydraulic pumps, cylinders and lines for functionality, leaks and pressure stability.

- Transmission and drive: Check the transmission and drive components for shifting operations, response behaviour and noise.

- Electrical systems: Test of the electrical systems, including lighting, displays, controls and battery.

- Brakes and steering system: Checking the braking performance and function of the steering system for safety and precision.

3. measurement of wearing parts:

- Tyres or tracks: check the degree of wear and general condition of the tyres or tracks.

- Bearings and joints: Check for play, wear and lubrication.

- Working tools: Checking buckets, buckets, blades or other attachments for wear and functionality.

4. fluid analyses:

- Oil analysis: checking engine oil, hydraulic oil and transmission oil for contamination, metal abrasion or other anomalies. More details about oil analysis.

- Coolant analysis: Checking the coolant for contamination and antifreeze capability.

5. safety inspection:

- Inspection of safety equipment: checking seat belts, safety bars, emergency stop switches and other safety devices.

- Noise and exhaust emissions: Measurement of noise and exhaust emissions to ensure they are within legal limits.

6. electronic systems and software:

- Diagnostic check: carrying out an electronic diagnostic test to read fault codes and check the function of the control units.

- Software updates: Ensuring that the machine is operated with the latest software version.

7. documentation:

- Test log: Detailed documentation of all tests performed and test results.

- Maintenance history: Provision of a complete history of all maintenance work, repairs and service intervals carried out.

- Certificate: Issue of a certificate confirming the condition and certification of the machine.

- Operating instructions: Ensuring that the current operating instructions are available and accessible.

- Safety documentation: Provision of all relevant safety documents and operating instructions.

8. test drive:

- Operational test: Carrying out a test drive under load conditions to check the performance and behaviour of the machine in real operation.

These comprehensive tests and the associated documentation ensure that the certified used machine meets the requirements and expectations in terms of safety, performance and reliability.