If you order a telescopic loader inspection you would receive a detailed report

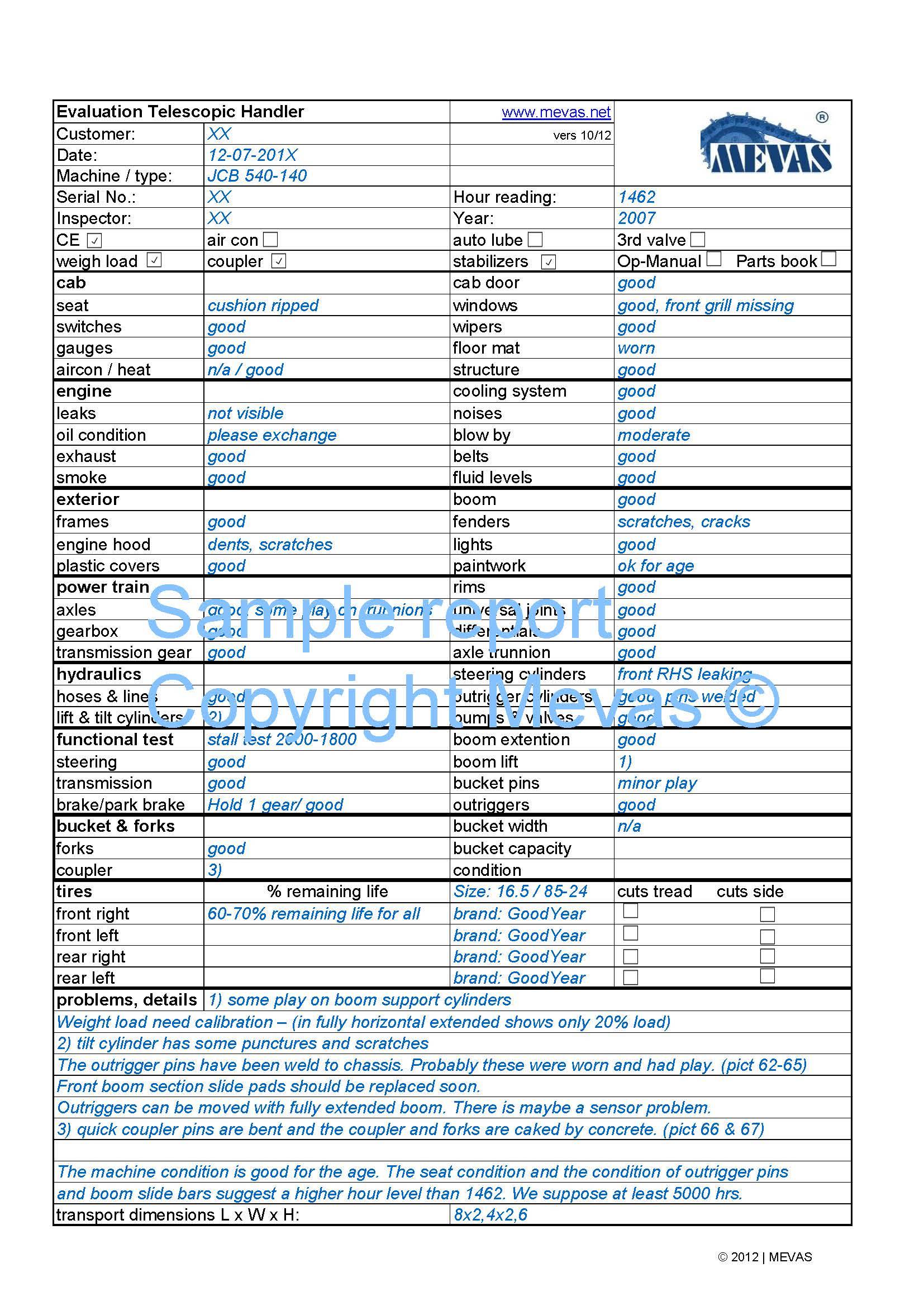

- Basic Machine information

- Operator Station condition

- Engine information and condition

- Condition of Exterior (chassis, boom, sheet metal, paint)

- Condition and performance of the Power Train

- Condition of Hydraulic system (pump, performance, hydraulic lines and cylinders)

- Functional test

- Remaining life of the Tires

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a telescopic loader inspection report in detail on our Google-Drive folder.

Video about telehandler inspection by Mevas

For some kind of machines we made a video about the inspection process. For a functional test of a telehandler inspection a video it is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What is a telehandler used for?

A telehandler, also known as a telescopic handler or a teleporter, is a versatile lifting machine widely used in construction, agriculture and industry. It is characterized by a telescopic boom, similar to a forklift, but with additional capabilities. The key feature of a telehandler is its ability to extend and retract the telescopic boom, allowing it to reach forward and upward to lift and place loads in areas that may be difficult to access with conventional forklifts.

Check list telehandler inspection

Here are eight main points to consider in a telehandler inspection:

- Structural Inspection:

- Check for any signs of damage or deformation in the frame, boom and chassis.

- Inspect welds for cracks or other abnormalities.

- Look for any loose or missing bolts.

- Telescopic Boom System:

- Inspect the telescopic boom for any visible damage.

- Check the extension and retraction mechanism for smooth operation.

- Verify that all locking pins are working properly.

- Hydraulic System:

- Check hydraulic hoses and connections for leaks.

- Inspect the hydraulic fluid level and ensure it meets the manufacturer’s specifications.

- Test all hydraulic functions, including lifting and tilting.

- Cabin/Controls:

- Verify that all controls, levers, and switches are in good working order.

- Check the instrument panel for warning lights or error codes.

- Test the functionality of safety features, such as emergency stop buttons.

- Tires:

- Inspect tires and rims for wear or visible damage.

- Brakes:

- Test the brake system including the park brake.

- Check for any unusual noises or vibrations during braking.

- Inspect brake pads and discs for wear.

- Safety Devices:

- Check all safety devices, such as overload sensors and limit switches.

- Verify the condition and operation of safety interlocks.

- Check the operator’s manual for any specific safety features unique to the telehandler model.

- Attachments and Accessories:

- Inspect any attachments or accessories for damage or wear.

- Ensure that attachment locking mechanisms are secure.

- Verify that quick-coupling systems are functioning properly.

A pre-delivery-inspection of used machinery is essential to prevent unforeseen issues and potential financial losses. It enables you to assess the equipment’s condition, identify hidden problems and negotiate a fair price. Have an experienced technician check the machine or contact Mevas for a thorough inspection.

What is a Telehandler and what is it used for?

A telehandler, also known as a telescopic handler or a telehandler forklift, is a versatile construction and agricultural equipment that combines the features of a forklift and a telescopic boom. It is designed to lift, move, and place loads using various attachments at the end of the boom. The key features of a telehandler include a telescoping boom, which can extend forward and upward, and a forklift attachment at the end of the boom. Telehandlers come with various attachments, such as forks, buckets, and hooks, allowing them to adapt to different tasks. The ability to extend the boom provides added reach and flexibility, making telehandlers a valuable piece of equipment in a wide range of industries.

- Material Handling: Telehandlers are used to lift and move materials to different heights and distances, making them valuable for construction sites, warehouses, and agricultural operations. They can handle palletized loads, construction materials, and other heavy objects.

- Construction: Telehandlers are widely used in construction for tasks such as placing and removing building materials, reaching elevated areas, and handling loads in tight or hard-to-reach spaces.

- Agriculture: In agriculture, telehandlers are employed for tasks like loading and unloading bales of hay, lifting and transporting bags of feed, and handling various materials on farms.

- Landscaping: Telehandlers are utilized in landscaping projects to move soil, plants, and other materials. The telescopic boom allows for reaching over obstacles or onto elevated surfaces.

- Maintenance and Repairs: Telehandlers are used for maintenance work in industrial settings and for repairing and installing equipment. The versatility of the telescopic boom makes them suitable for tasks that require reach and height.

- Utilities: Telehandlers are employed by utility companies for tasks such as lifting and placing utility poles, handling equipment for power line maintenance, and accessing elevated work areas.

Liste de contrôle pour une chariot télescopique ou chariot élévateur

Tu trouveras ici un exemple de liste de contrôle pour une chariot télescopique ou chariot élévateur. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.