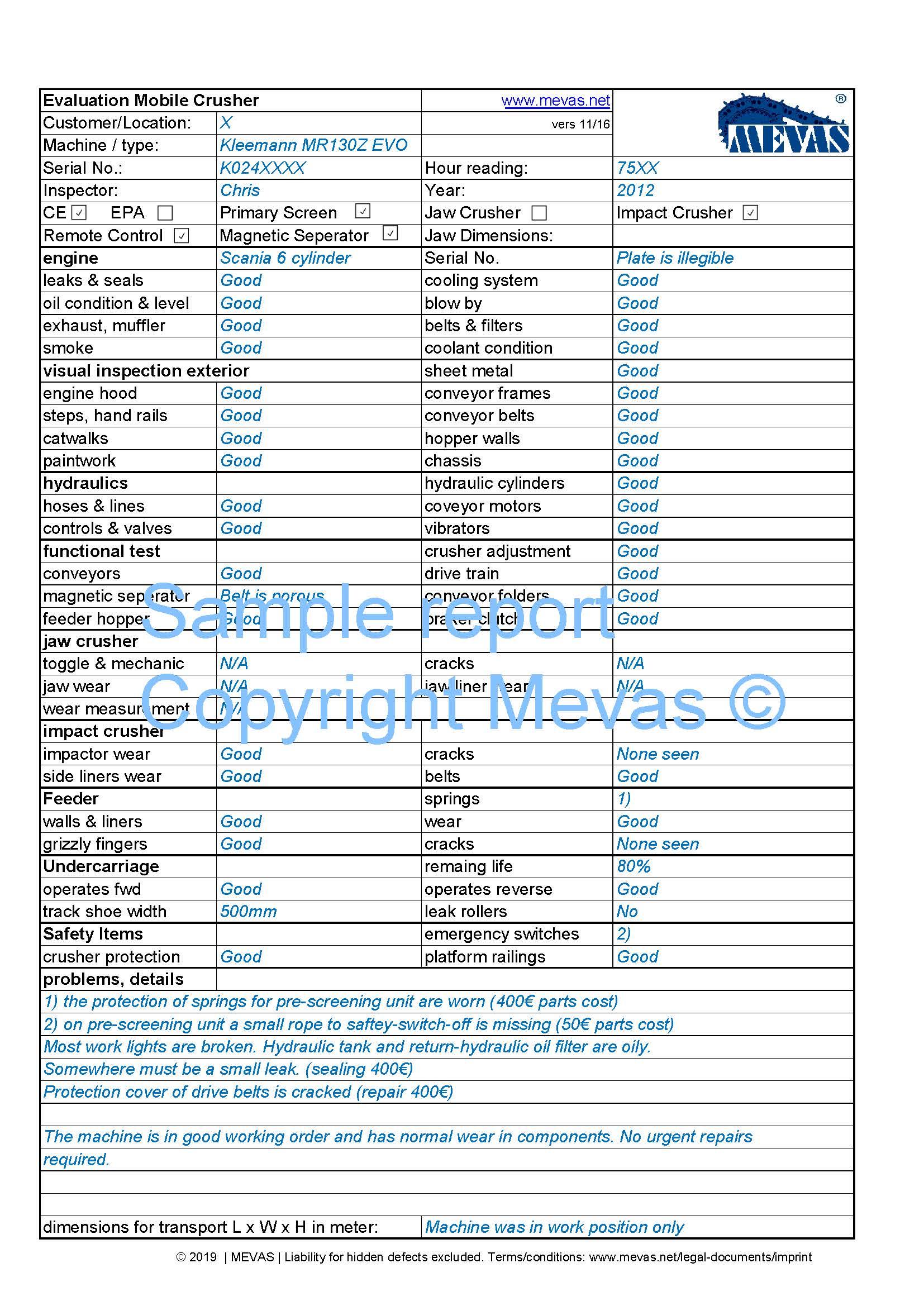

During the inspection of a used rock crusher we check those items and write an inspection report

- Basic Machine information and configuration

- Engine information and condition

- Condition of Exterior (chassis, sheet metal, conveyor belts and frames)

- Condition of hydraulic system (hoses, valves, cylinders, vibrators, motors)

- Functional test as far as possible

- Wear of Jaw or Impact crusher (also possible for cone crusher)

- Condition of the Feeder, Hoper, Bunker

- Test of forward/reverse operation

- Functional check of Safety items

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see an inspection report for an impact crusher in detail on our Google-Drive folder.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

Checklist for crusher inspections

When inspecting and comparing impact crushers and jaw crushers, there are some specific points to consider for each type of crusher. Here’s a checklist highlighting the key differences for both types of machines.

Take a close look at the following points during an inspection of a pre-owned impact crusher:

- Exterior: Check for visible wear, rust or damages.

- Structure: Inspect the frame for any damage or structural issues.

- Rotor and Crushing Chamber: Examine the rotor, hammers and crushing chamber for wear.

- Bearings: Check bearings for wear and proper lubrication.

- Feed System: Inspect the feed hopper and conveyor for damage.

- Drive System: Examine the motor, gearbox and drive belts for wear and alignment.

- Hydraulic System: Check hydraulic hoses and cylinders for leaks.

- Electrical Components: Ensure all electrical components are working.

- Safety Features: Check the guards and the emergency stop functionality.

- Documentation/Testing: Review maintenance records, user manuals, and conduct a test run (if possible with material).

And here is the checklist for the inspection of jaw crushers:

- Jaw Plates: Examine the jaw plates for wear and assess the need for replacements.

- Bearings: Inspect bearings for wear or play.

- Toggle Plate and Toggle Seat: Check for wear and proper alignment.

- Eccentric Shaft: Inspect for damage or misalignment.

- Flywheel: Examine for balance and signs of wear.

- Hydraulics: Check for leaks, proper pressure and functionality.

- Drive System: Inspect the motor, belts, and pulleys for wear, alignment, and tension.

- Clearance and Adjustment: Confirm settings and test adjustment mechanisms for smooth operation.

- Electric: Check the electrical system, including wiring, switches and control panels.

- Safety items: Verify the presence and functionality of safety features such as guards and emergency stops.

- Functional test: Carry out a function test. If possible, use some material to check how the machine works.

Video about inspections by Mevas

For some kind of machines we made a video about the inspection process. Check out our YouTube-Channel.

What is a rock crusher and what is it used for?

- Mining: In mining operations, crushers are used to break down the extracted ore or minerals into smaller, more manageable pieces. This makes it easier to transport and process the materials further.

- Construction: Rock crushers are employed in construction projects for breaking down large rocks into smaller, more manageable sizes for use in construction materials like concrete, asphalt, and other building materials.

- Quarrying: In the quarrying industry, crushers are used to break down the extracted rock into smaller pieces that can be used for various construction purposes. This includes aggregates used in concrete production.

- Recycling: Crushers are often used in recycling operations to break down materials such as concrete, asphalt, and other construction waste into reusable materials.

- Demolition: In demolition projects, rock crushers are used to break down structures and buildings by crushing the concrete and other materials.