If you order a compaction roller inspection, we will provide you with a detailed overview of the machines condition

Prior the purchase of an used compactor, roller, tandem vibratory roller or single drum roller, you should check its condition carefully. This will save you downtime and costs. If you book a complete inspection with Mevas, you will receive the following checklist:

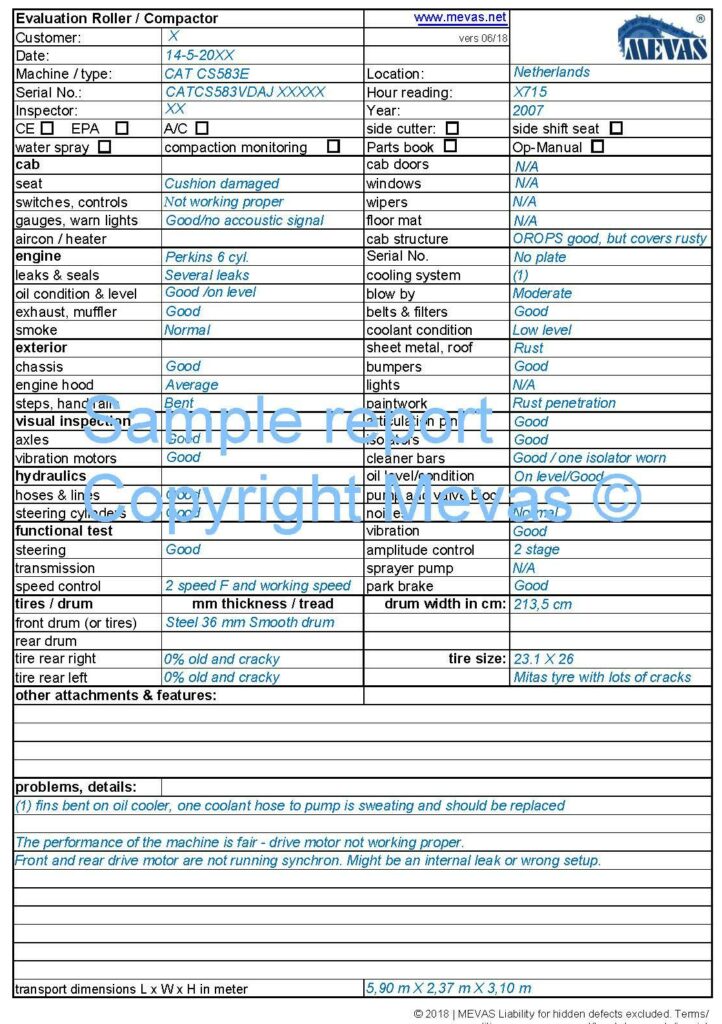

- Basic Machine information and configuration

- Operator Station details and condition

- Engine information and condition

- Condition of Exterior (chassis, sheet metal, drum, paint, tanks)

- Visual inspection of important components (axles, drive motors, pins, isolators)

- Condition of the Hydraulic system (pump, performance, hydraulic lines and cylinders)

- Functional test, vibration test

- Condition of the drum and the tires

- Comments about condition and recommendation for repairs

- Transport dimensions

60-point Checklist. The version in picture is obsolete. With ordering an inspection you would receive the latest version of our inspection form.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a compaction roller report in detail on our Google-Drive folder.

Video about our inspection service

For some kind of machines we made a video about the inspection process. There is currently no video available for the inspection of a roller, but for an impression of our work, take a look at our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What kind of compaction equipment for road construction and land fill is known and what are the key components of it?

Compaction equipment is essential in both road construction and landfill operations to ensure proper compaction of soil, aggregates, and waste materials. Some common types of compaction equipment include:

- Vibratory Rollers: Vibratory rollers are perhaps the most common compaction equipment used in road construction and landfill operations. These machines use vibrating drums or plates to compact soil or aggregates by applying dynamic forces.

- Static Rollers: Static rollers, also known as smooth-wheeled rollers, compact materials by applying static weight evenly across the surface. They are effective for achieving final compaction on asphalt layers and landfill covers.

- Pneumatic Rollers: Pneumatic rollers use rubber tires instead of steel drums. They are effective for compacting asphalt pavements and for achieving a smooth finish.

- Tamping Compactors: Tamping compactors, or rammers, are small, handheld machines used for compacting small areas or confined spaces where larger equipment cannot reach.

- Landfill Compactors: Specifically designed for landfill operations, landfill compactors are heavy-duty machines equipped with steel wheels or tamping feet. They compact waste materials to reduce airspace and increase landfill capacity.

Key components of compaction equipment include:

- Drums or Plates: These are the primary compaction elements of vibratory rollers. They can be smooth or padded, depending on the type of material being compacted.

- Engine: Compaction equipment is powered by internal combustion engines, which provide the necessary power to operate the machine.

- Hydraulic System: Compactors rely on hydraulic systems to control various functions such as steering, vibration frequency, and drum pressure.

- Frame and Chassis: The frame and chassis provide structural support to the compaction equipment and house other components such as the engine and hydraulic system.

- Operator Controls: These include steering wheels, joysticks, levers, and other controls that allow the operator to maneuver the machine and adjust compaction parameters.

- Water Spray System: Some compaction equipment, especially those used for asphalt compaction, are equipped with water spray systems to prevent the material from sticking to the drums or plates.

- Safety Features: Compaction equipment is equipped with safety features such as roll-over protection systems (ROPS), seat belts, and warning lights to ensure operator safety during operation.

Proper selection and operation of compaction equipment are crucial for achieving desired compaction densities and ensuring the long-term stability of roadways and landfills. Call Mevas for a pre-purchase inspection of compaction machinery. It pays off.

Liste de contrôle pour une rouleau monocylindre ou rouleau tandem

Tu trouveras ici un exemple de liste de contrôle pour une rouleau monocylindre ou rouleau compaction tandem. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.