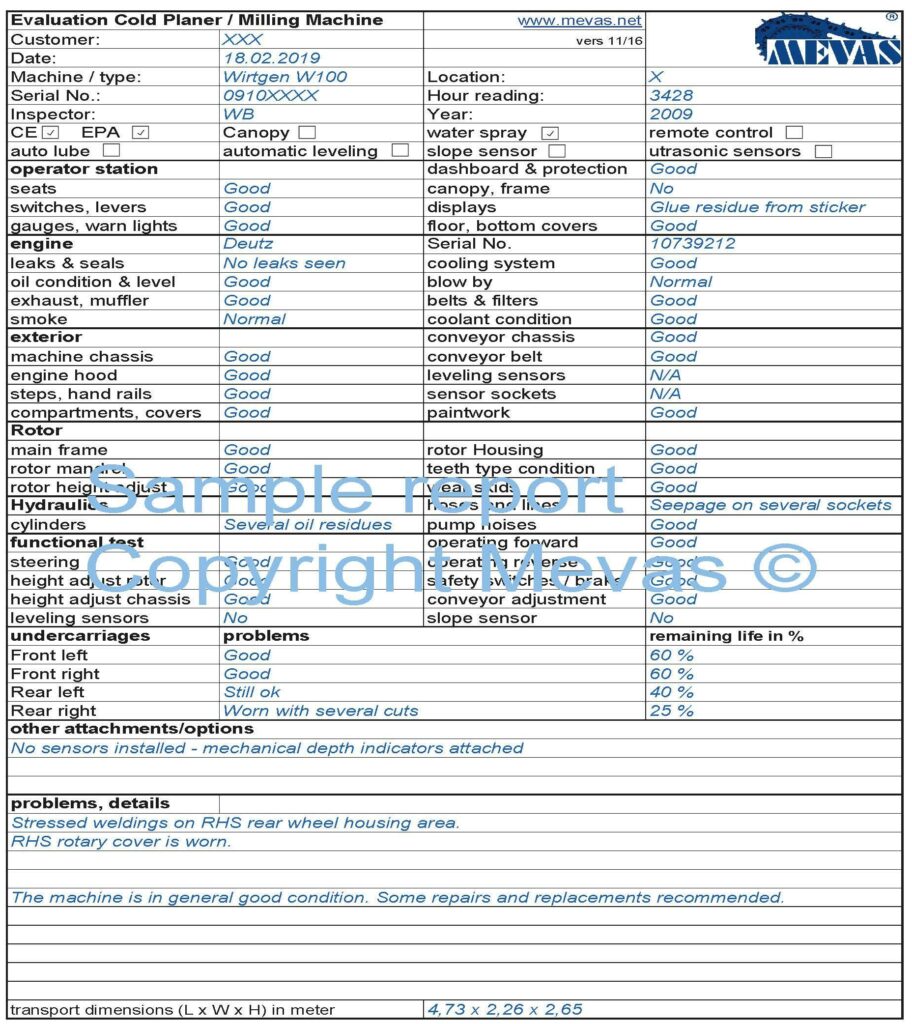

If you order an Cold Planer inspection you would receive a detailed report

- Basic Machine information and configuration

- Operator Station details and condition

- Engine information and condition

- Condition of the Exterior (chassis, sheet metal, conveyor, sensors)

- Condition of the Rotor and Hydraulic system (pump, performance, cylinders)

- Functional test incl. height adjustment

- Remaining life of the Undercarriage

- Comments and recommendation for repairs

- Transport dimensions

- Hour verification if machine has a CAT engine

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a milling machine inspection report in detail on our Google-Drive folder.

Video about Milling machine inspection by Mevas

For some kind of machines we made a video about the inspection process. For a Milling Machine an inspection a video is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What is a cold planer and what is it used for?

A cold planer, also known as a pavement milling machine or asphalt milling machine, is a piece of heavy equipment used in road construction and maintenance. It is primarily used for removing layers of asphalt or concrete from roads, highways, parking lots, and other paved surfaces.

How does a cold planer work?

- Rotating Drum: The cold planer features a large rotating drum with cutting teeth or bits attached to it. This drum spins rapidly and grinds away the pavement surface.

- Depth Control: The depth of the cut can be adjusted depending on the requirements of the project. This allows workers to remove precise amounts of pavement to achieve the desired depth.

- Material Removal: As the cold planer moves forward, the rotating drum cuts into the pavement, removing the unwanted material. The removed material is typically collected by a conveyor belt and deposited into a waiting truck for disposal or recycling.

Cold planers are used for several purposes:

- Pavement Rehabilitation: They are used to remove worn-out or damaged pavement surfaces, preparing the area for new pavement overlays.

- Surface Texture Improvement: Cold planers can also be used to improve the surface texture of existing pavement, creating a smoother and more even surface.

- Leveling Uneven Surfaces: They are effective in leveling uneven surfaces caused by rutting, potholes, or other forms of pavement distress.

- Creating Drainage Slopes: Cold planers can be used to create proper drainage slopes on road surfaces, ensuring that water drains away effectively and reducing the risk of flooding or water damage.

Overall, cold planers play a crucial role in maintaining and improving the quality and safety of paved surfaces on roads and other infrastructure projects.