If you order a crawler crane inspection you would receive a detailed report

- Basic crane information and configuraton

- Condition of the operator cab

- Engine information and condition

- Condition of the exterior

- Functional test (winch, cylinders, brakes, steering, electronics)

- Remaining lift of the undercarriage

- Comments and recommendation for repairs

- List of attachments on site

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

During a crane inspection the engineer is checking all crane components for condition and damage. With the local operator a test of all crane functions will be performed. Crane erected, boom fully telescoped, outriggers on ground, test of winches and swing drive. We measure swing bearing play and rope diameter. Finally a drive and brake test is done. Once you receive an offer it will be always for a this scope of inspection. If you need additional services such as analysing the engine oil, we can do this for you. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

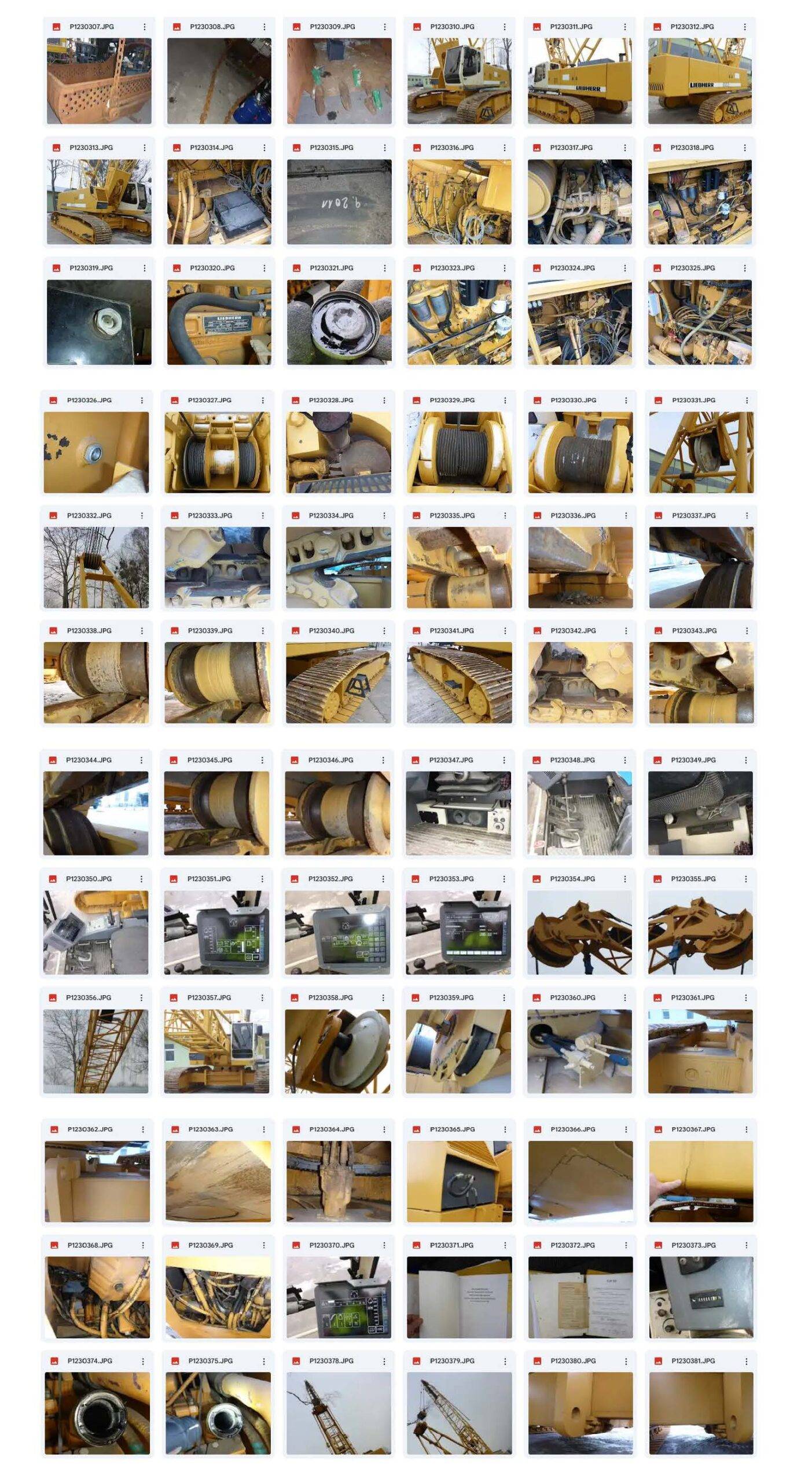

Pictures and video coming with a Mevas-Report

Each crane inspection comes along with 70-150 pictures and in some cases with a short video. In case of interest it is possible to see an sample report in detail on our Google-Drive folder.

Video about Mevas crane inspection

We created a video about the inspection process of a construction machines and cranes. Feel free to take a look at our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

Checklist for crawler cranes

A pre-purchase inspection of an used crawler crane is essential to identify hidden problems and negotiate a fair price based on the actual condition of the crane. You should check the following things:

1. Structure:

- Check the structure for any signs of damage, cracks, or weld defects.

- Inspect the boom, jib and counterweight for cracks, deformation or corrosion.

2. Engine:

- Visual check for any signs of leaks.

- Check the engine oil and the coolant level.

- Start the engine and listen for any unusual noises.

- Check the exhaust system for abnormal smoke.

- Monitor engine gauges and instruments for normal readings, including oil pressure, coolant temperature, and charging voltage.

3. Hydraulics:

- Check hoses and fittings for leaks or damages.

- Check if the hydraulic fluid levels are within the recommended range.

- Test hydraulic cylinders for proper operation and signs of leakage.

4. Undercarriage:

- Check for wear and tear on the tracks, pads, and track rollers.

- Ensure proper tension in the track chains.

- Look for any signs of track misalignment or damage.

5. Electrics:

- Test all lights, indicators and alarms for proper operation.

- Inspect wiring harnesses for damages.

- Check batteries for proper functioning.

6. Safety devices:

- Ensure that all safety devices such as limit switches and load moment indicators are working correctly.

- Test emergency stop buttons and other safety controls.

7. Brakes:

- Test the braking system (including parking brake) for effectiveness.

- Inspect brake pads, discs, and drums for wear and tear.

8. Cab:

- Inspect the operator cab for functionality and visibility.

- Check controls, levers and gauges for proper operation.

- Test all safety features such as seat belts and operator restraint systems.

9. Load Testing:

- Periodically conduct load tests to ensure the crane can safely lift its maximum rated load.

- Follow manufacturer guidelines for load testing procedures.

10. Fluid Analysis:

- Consider conducting fluid analysis (oil, hydraulic fluid, etc.) to assess the condition of internal components.

11. Documentation and Maintenance Records:

- Review the crane’s maintenance records and any available documentation.

- Check the crane’s history, including any past accidents or repairs.

Make sure that a technician who is familiar with crawler cranes checks it or contact Mevas. We inspect a large number of cranes of various types every year and will be happy to help you.

Inspection for mobile and harbor cranes

Our experienced team of inspectors is available for inspection of any kind of cranes. Mevas inspects more the 100 mobile cranes per year and knows also about inspection and valuation of harbor cranes.