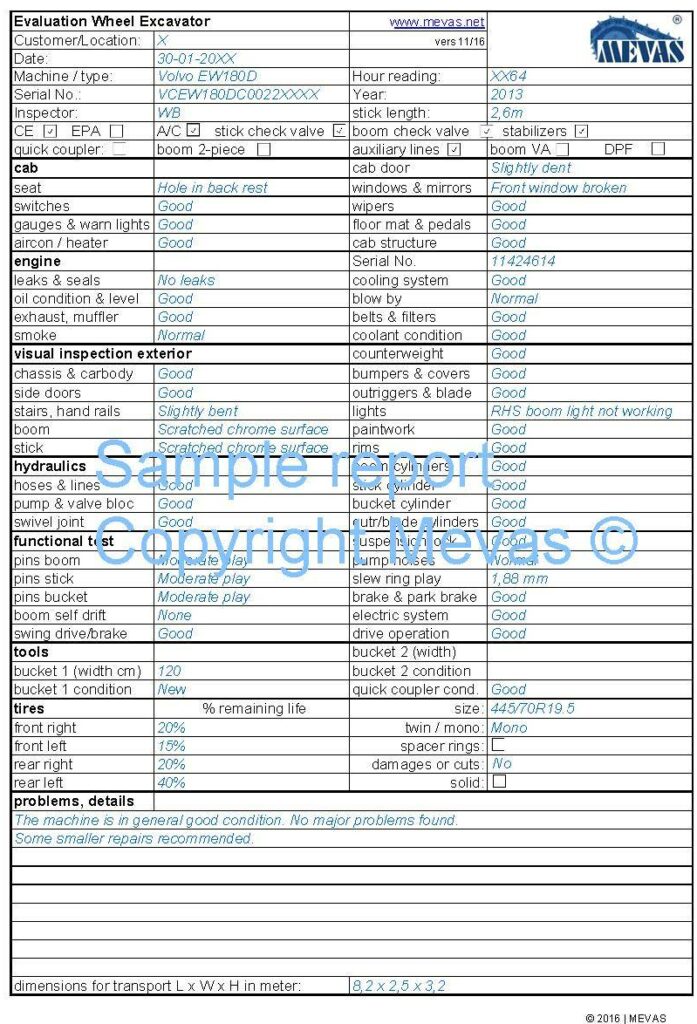

Sample of an inspection checklist for a used wheel-excavator

Before negotiating the sale of a used mobile excavator you should check its condition carefully. This will save you downtime and costs. If you book a complete inspection with Mevas, you will receive the following 60-point checklist:

- Basic Machine information and Configurations (boom, stick, stabilizers)

- Operator Station details and condition (air condition, accu grade, cab lifter)

- Engine information and condition (emission status)

- Visual Condition (chassis, boom, stick, outriggers)

- Condition of the Hydraulic system (pump, performance, hydraulic lines and cylinders)

- Functional test

- Condition of the attached tools

- Remaining life of the tires

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report for a mobile excavator below. On request we can send a PDF-version of such a report.

The pictured report is an obsolete version. With ordering an inspection you would receive the latest checklist version.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each wheel excavator inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a mobile excavator report in detail on our Google-Drive folder.

Video about excavator inspection by Mevas

For some kind of machines we made a video about the inspection process. For an excavator inspection a video it is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What are the advantages of a mobile excavator?

Mobile excavators offer several advantages compared to traditional excavators, especially in construction and earthmoving applications. Some of the key advantages include:

- Mobility: As the name suggests, mobile excavators are designed to be easily transported from one job site to another. They can be driven on roads, making them highly versatile and suitable for projects that require frequent relocation.

- Versatility: Mobile excavators are equipped with various attachments and tools that allow them to perform a wide range of tasks such as digging, lifting, and loading materials. They can be used in diverse applications including road construction, landscaping, utility work, and demolition. Many of them have a varialble boom of two pieces which enables longer reach, cloder oeration and deeper digging.

- Compact Design: Mobile excavators are often more compact compared to traditional excavators, making them suitable for operating in tight spaces and urban environments where space is limited. Their compact design also makes them easier to maneuver around obstacles on the job site.

- Lower Operating Costs: Mobile excavators typically have lower operating costs compared to larger, tracked excavators. They consume less fuel due to their smaller engines and are often more fuel-efficient, resulting in cost savings over time.

- Ease of Maintenance: Mobile excavators are designed for easy maintenance and serviceability. Components such as the engine, hydraulic system, and other parts are easily accessible, making routine maintenance tasks more straightforward and less time-consuming.

- Increased Productivity: With their mobility and versatility, mobile excavators can help increase productivity on the job site by performing various tasks efficiently. They can quickly switch between different attachments and adapt to changing project requirements, minimizing downtime and delays.

- Accessibility: Mobile excavators can access areas that may be difficult for larger excavators to reach, such as confined spaces or areas with limited access or. This accessibility makes them particularly useful for projects in urban areas or tight construction sites. Driving on asphalt or plaster is often not possible with tracked excavators.

Liste de contrôle pour une pelle sur pneu

Tu trouveras ici un exemple de liste de contrôle pour une excavatrice de pneu. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.