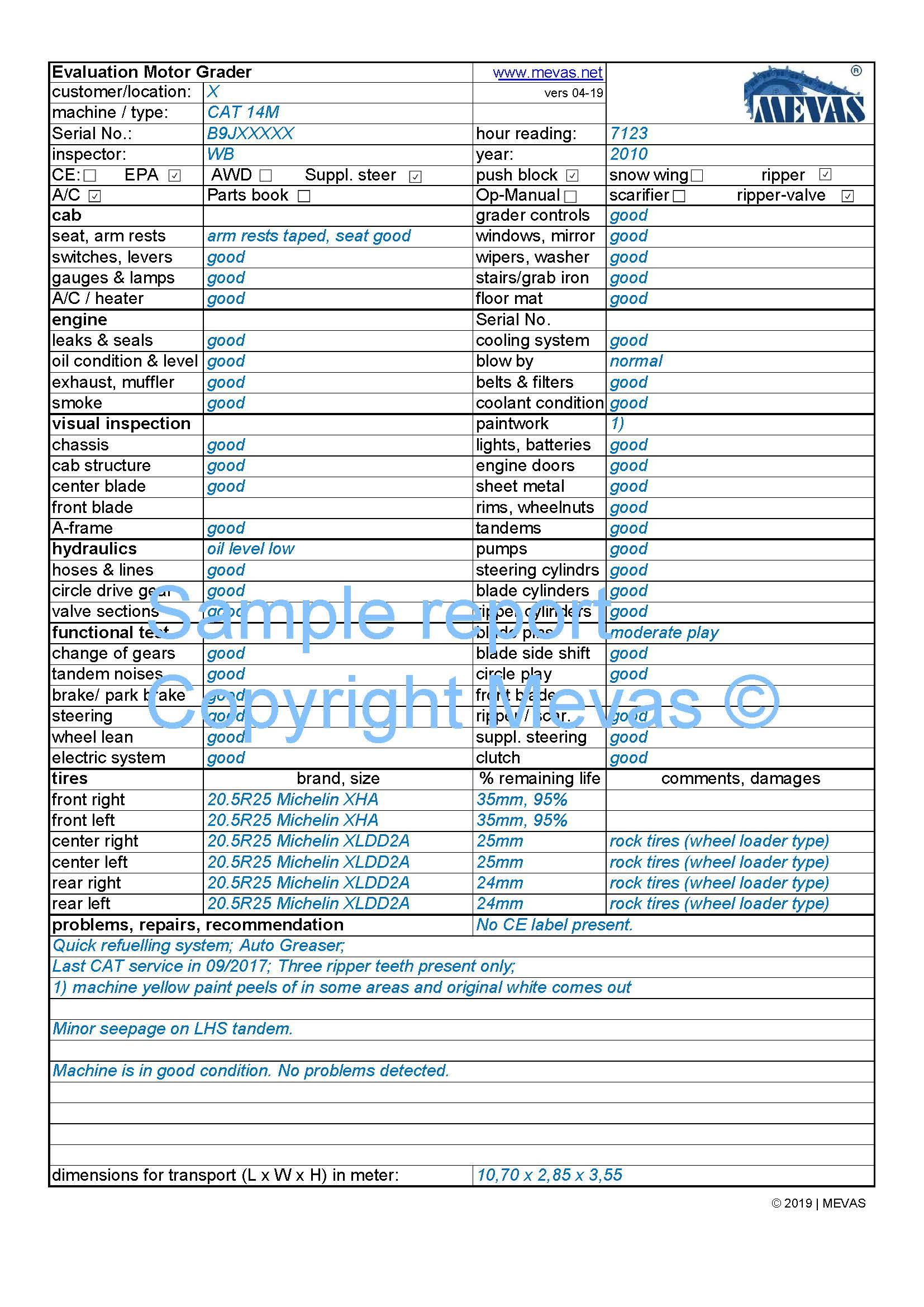

If you order a Motor Grader inspection you would receive a detailed report

- Basic Machine information

- Operator Station details and condition

- Engine information and condition

- Visual condition of Exterior (chassis, structure, blades, tandems)

- Condition of the Hydraulic System (pumps, valves, cylinders)

- Functional test

- Condition of the Tires

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see an motor grader report in detail on our Google-Drive folder.

Video about a grader inspection by Mevas

For some kind of machines we made a video about the inspection process. For a grader inspection a video it is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What is a motor grader and which components should be checked in particular when buying a used machine?

A motor grader, also known as a grader or road grader, is a construction machine with a long blade used to create a flat surface during the grading process. It is commonly used for leveling and smoothing the surface of roads, parking lots and other large, flat areas. Motor graders typically have three axles, with the engine and cabin situated above the rear axles and the grader blade in front.

When buying a used motor grader, it’s crucial to thoroughly inspect various components to ensure that the machine is in good condition. Here are some key components to check:

Engine

- Inspect the engine for any signs of leaks, excessive smoke or unusual noises.

- Check the engine hours to get an idea of its overall usage.

- Look for maintenance records and ensure that regular servicing has been performed.

Transmission & Tandems

- Test the transmission by engaging different gears and checking for smooth operation.

- Look for any signs of fluid leaks around the transmission area.

- Check the tandems for play in main bearings, leaks and wear in chains.

Frame and Structure

- Inspect the frame for signs of damage or excessive wear.

- Check for any signs of welding or repairs that may indicate prior damage.

- Have a close look to the A-Frame and hinges of circle frame.

Blade

- Examine the grader blade for wear, cracks or any signs of damage.

- Check the blade lift system for smooth operation and signs of leaks.

- Check the play in side shift guides.

- Check the base for wear and if bolts and nuts are OK.

Tires & Steering system

- Inspect the tires for wear and ensure they are evenly worn.

- Check for any cuts, bulges or other damage to the tire sidewalls.

- Check the wheel lean function and tie rods.

- Check the central articulation and steering.

Brakes

- Check the braking system for effectiveness and signs of wear.

- Check if service brake is working on all wheels

- Ensure that the parking brake is functioning correctly.

- Check charging time for air brake system and for air leaks.

What else?

Listed are the most important items. If you are not familiar with motor graders send an expert such as a Mevas-Engineer.

Liste de contrôle pour une niveleuse

Tu trouveras ici un exemple de liste de contrôle pour une niveleuse. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.