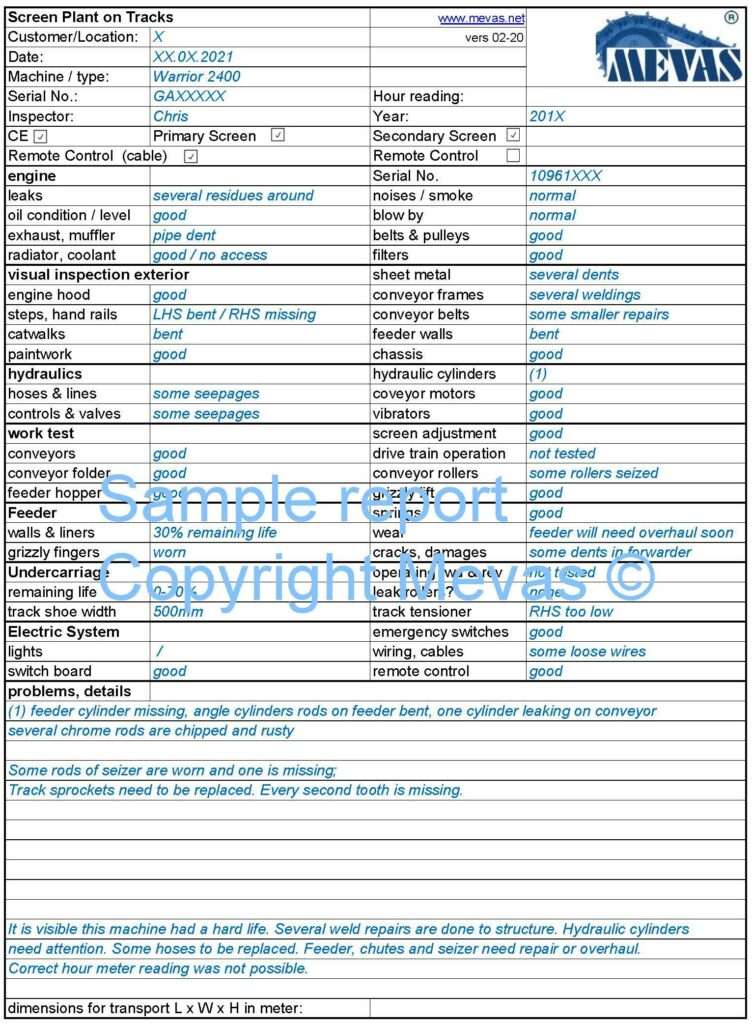

Inspection Checklist for a screen plant inspection

Mevas is your global operating expert for inspection of used screen plants. Whether in quarry, open sand pit or a recycling application. We are available for a proper and professional inspection of the condition and estimation of remaining life on components.

Those item will be reported and rated:

- Basic Machine information

- Engine information and condition

- Condition of Exterior (chassis, sheet metal, conveyor)

- Condition of Hydraulics (controls and valves, motors and cylinders)

- Functional test

- Condition of the Feeder

- Remaining life of the Undercarriage

- Condition of the Electrics

- Comments and recommendation for repairs

- Transport dimensions

- Full inspection checklist

This picture shows an outdated version of our inspection form. With ordering an inspection you would receive the latest checklist version.

Book a screen plant inspection with us

Our inspectors are available in more than 25 countries. In most cases an engineer is less than 300km away from a machine in Europe.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a screen report in detail on our Google-Drive folder.

Video about machinery inspections by Mevas

For some kind of machines we made a video about the inspection process. Feel free to visit our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What is a Recycling Screen Plant and what are the major components of such a machine?

A Recycling Screen Plant is a piece of equipment used in recycling facilities to sort and process recyclable materials such as plastics, paper, glass, metals, and others. The primary function of a Recycling Screen Plant is to separate mixed materials into different categories based on size, shape, and material type so that they can be efficiently processed for recycling. The same type of machine is used in open sand pits to classify gravel in different sizes from sand to larger rocks. In quarries it is used also to sort raw material into different sizes for different applications in the construction industry.

The major components of a Recycling Screen Plant typically include:

Feed Hopper: This is where the mixed recyclable materials or the raw gravel are initially deposited into the machine for processing.

Conveyor Belts: These belts transport the materials through the different stages of the screening process. They may be inclined or horizontal, depending on the design of the plant.

Screening Deck: The screening deck consists of a series of screens or sieves with different sized openings. As the material moves along the conveyor belt, it passes over the screens, allowing smaller particles to fall through while larger ones continue along the conveyor.

Vibrating Screens: Vibrating screens are used to shake the materials as they move over the screening deck. This helps to separate materials based on size and prevents clogging or blockages in the screens.

Trommel: A trommel is a cylindrical drum with perforated metal plates or screens. It rotates as the material moves through it, allowing smaller particles to fall through while larger ones are carried to the end of the trommel. Often used to screen wet soil and earth.

Air Classifiers: Air classifiers use air streams to separate lighter materials such as paper and plastic from heavier materials like glass and metals. The lighter materials are blown upward while the heavier materials fall downward, allowing for separation.

Eddy Current Separators: These separators use magnetic fields to repel non-ferrous metals such as aluminum and copper from the rest of the materials. The metals are then collected separately for recycling.

Who are the main producers of screen plant for sand pits and quarries?

The main producers of screen plants for sand pits and quarries are a mix of global equipment manufacturers specializing in mobile and stationary screening solutions. These companies provide a range of screening equipment designed for the aggregate, mining, and recycling industries. Below are the leading producers:

Major Manufacturers of Screening Plants

Powerscreen

- Recognized as a world leader in manufacturing crushers, screeners, and conveyors, Powerscreen pioneered mobile screening technology and remains a top supplier for sand pits and quarries worldwide.

Metso

- Metso offers a comprehensive portfolio of stationary and mobile screens, including inclined and horizontal models, designed specifically for aggregates production, quarries, gravel pits, and mining operations.

Sandvik Mobile Crushers & Screens

- Sandvik is known for its advanced Doublescreen technology and mobile screening plants, such as the QA452, which are engineered for high performance in quarry and sand pit applications.

Astec Industries

- Astec manufactures a variety of mobile screening plants, such as the GT2612V, featuring high-frequency screens suitable for sizing sand, gravel, crushed stone, and recycled materials.

EvoQuip

- EvoQuip’s Falcon series, including the Falcon 820, provides compact and versatile finishing screens for sand, gravel, and demolition waste processing.

Screen Machine

- Specializes in portable screening equipment for aggregates and mining, offering mobile solutions for sand pits and quarries.

KPI-JCI and Astec Mobile Screens

- Produces a wide range of horizontal, inclined, and high-frequency screens for screening sand, gravel, and other aggregates in both portable and stationary configurations.

Other Notable Producers and Suppliers

- Hazemag, Superior Industries, Conn-Weld, Haver & Boecker Niagara, Syntron Material Handling, Deister: These companies supply key components and complete screening solutions for quarries and sand pits.

- The Western Group, SWECO, Rotex, Midwestern Industries, JVI Vibratory Equipment: Offer a variety of custom and standard screens, including vibratory and high-frequency models, for aggregate applications.

- KÜPER: Specializes in efficient screen panels for sand and gravel applications, focusing on maximizing open area and minimizing clogging.

Summary Table

| Manufacturer | Key Products/Features | Application Focus |

|---|---|---|

| Powerscreen | Mobile screeners, conveyors | Aggregates, mining, recycling |

| Metso | Inclined/horizontal screens, mobile & static | Quarries, gravel pits, mining |

| Sandvik | Doublescreen mobile plants | Quarries, recycling, mining |

| Astec Industries | High-frequency mobile screens | Sand, gravel, crushed stone |

| EvoQuip | Compact finishing screens | Sand, gravel, demolition waste |

| Screen Machine | Portable screening equipment | Aggregates, mining |

| KPI-JCI & Astec Mobile Screens | Horizontal, inclined, high-frequency screens | Sand, gravel, aggregates |

These companies are the primary suppliers of screening plants and equipment used in sand pits and quarries globally, offering a range of solutions tailored to the demands of the aggregates industry.

Citations:

- https://www.pitandquarry.com/the-latest-in-portable-screening-equipment/

- #

- https://www.pitandquarry.com/components-to-consider-for-screening-plants/

- https://www.powerscreen.com

- #

- #

- https://www.quarrymagazine.com/sifting-through-the-facts-selecting-a-mobile-screen/

- https://www.rubblemaster.com/us/company/blog/a-quick-guide-to-choosing-the-right-mobile-screening-plant-for-your-business

- https://kuepergermany.com/en/portfolio/sand-gravel/

Liste de contrôle pour une installation de criblage

Tu trouveras ici un exemple de liste de contrôle pour une installation de criblage. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.