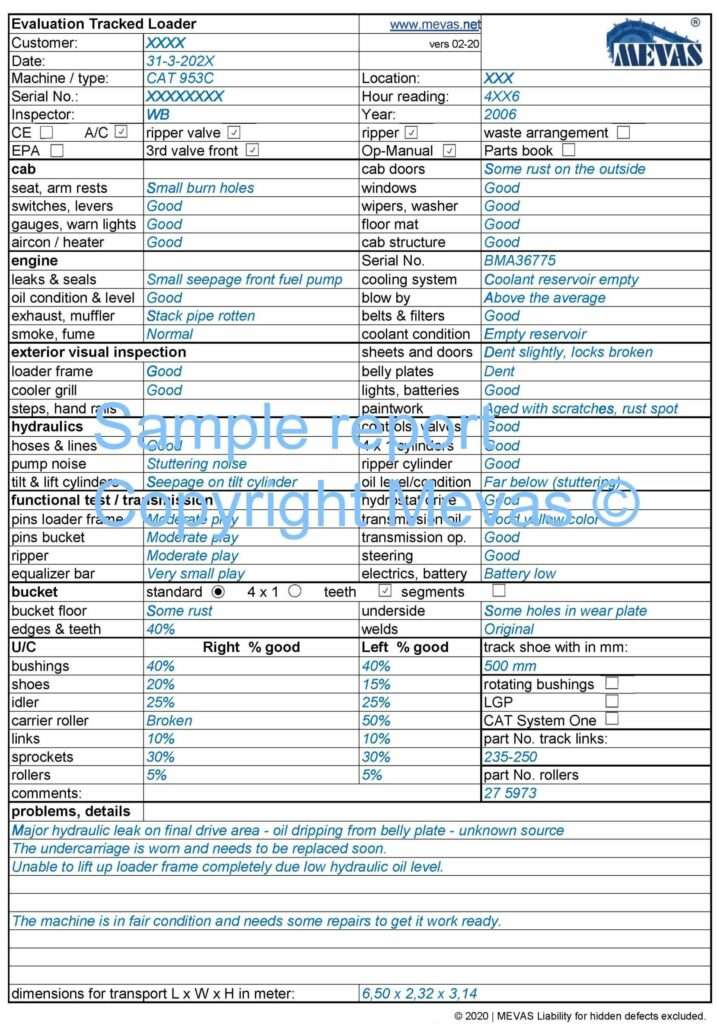

If you order a Track loader inspection you would receive a detailed report

- Basic Machine information and configuration

- Operator Station details and condition

- Engine information, condition and performance

- Condition of the Exterior (chassis, grill, sheet metal, paint)

- Condition of the Hydraulic system (pump, performance, cylinders, hoses)

- Functional test (play in pins, transmission, steering etc.)

- Remaining life of the Undercarriage (bushings, shoes, idlers, rollers, links, sprockets)

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail. By the way, we inspect track loaders including measurement of track remaining life since 2006.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see an track loader report in detail on our Google-Drive folder.

Video about an Track loader inspection by Mevas

For some kind of machines we made a video about the inspection process. For an tracked loader inspection a video it is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What is a track loader and what is it designated for?

A track loader is a type of construction equipment used for a variety of tasks across different industries such as land clearing, digging, grading, truck loading, slope work and more. It shares similarities with a wheel loader but even more with a bulldozer and is equipped with tracks instead of wheels.

Details for track type loaders

- Tracks: Track loaders feature steel tracks instead of wheels, which provide enhanced traction and flotation, particularly in rough or soft terrain. The tracks also help distribute the machine’s weight more evenly, reducing ground pressure and minimizing damage to sensitive surfaces.

- Compact Design: Track loaders have a relatively compact and heavy design, making them well-suited for working in confined spaces and on uneven terrain where larger equipment may have difficulty maneuvering.

- Versatility: Track loaders are highly versatile machines capable of performing a wide range of tasks. They can be equipped with various attachments, such as buckets, forks, augers, grapples, and hydraulic breakers, to handle tasks such as loading, digging, grading, material handling, and site cleanup.

- Lift Capacity: Track loaders come in different sizes and configurations, with varying lift capacities ranging from several hundred pounds to several thousand pounds. The lift arms on track loaders are hydraulically operated, allowing for efficient lifting and dumping of materials.

- Applications: Track loaders find applications in construction, landscaping, agriculture, forestry, and other industries. They are commonly used for tasks such as loading and transporting materials, excavating and backfilling trenches, grading and leveling terrain, clearing brush and debris, and performing snow removal operations.

- Operator Comfort and Safety: Modern track loaders are equipped with features designed to enhance operator comfort and safety, such as ergonomic controls, adjustable seating, enclosed cabs with heating and air conditioning, and advanced safety systems.

- Well known brands: Most common are products from Caterpillar such as the 953 or 963 loader. Also Liebherr and some others are producing it. However, the market is specific and small. Most track loaders come with a hydrostatic drive train.

Liste de contrôle pour une chargeuse sur chenilles

Tu trouveras ici un exemple de liste de contrôle pour une chargeuse chenilles. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.