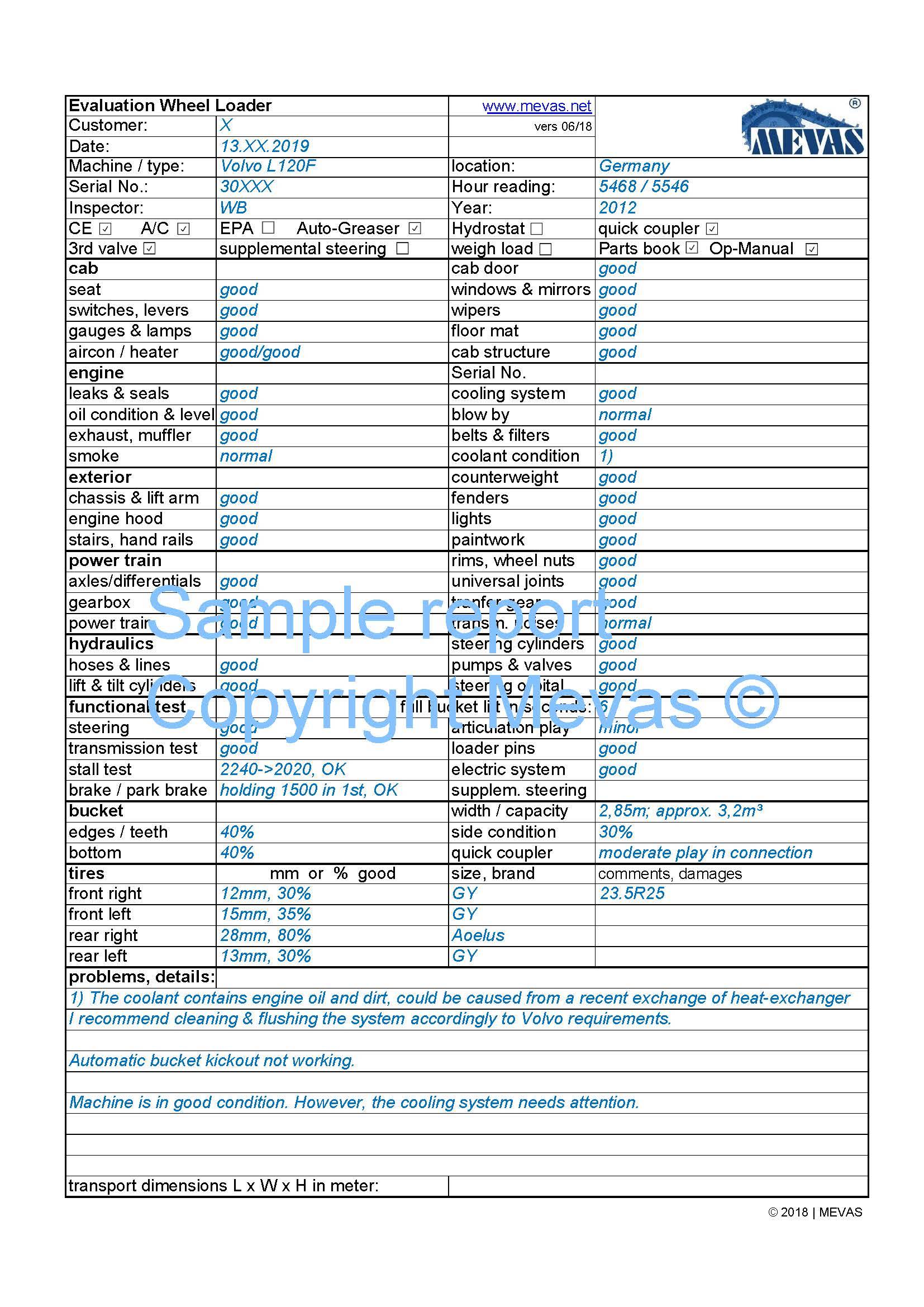

If you order a wheel loader inspection you would receive a detailed checklist

Mevas is your experienced partner for the inspection of used wheel loaders worldwide. Whether in the quarry, on the construction site or on the dealer’s sales premises. We are at your disposal for a professional inspection of the condition and remaining service life.

- Basic Machine information

- Cabin details and condition

- Engine information and condition

- Condition of Exterior (chassis, lift arm, engine hood, lights, paint)

- Condition of Power Train

- Condition of Hydraulic system (pump, performance, hydraulic lines and cylinders)

- Functional test

- Condition/remaining life bucket and tires

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. This version is not up to date. The latest report version comes with an inspection.

What extras can you order?

Once you receive an offer, it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see a wheel loader inspection report in detail on our Google-Drive folder.

Video about excavator inspection by Mevas

For some kind of machines we made a video about the inspection process. For a wheel loader inspection a video it is available on our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What points and tests should a condition inspection of a used wheel loader include?

Inspecting a used wheel loader thoroughly is essential to ensure that it is in good condition and meets your operational requirements. Here’s a comprehensive checklist for a condition inspection of a used wheel loader:

- Overall Inspection:

- Check for visible signs of damage, rust, or welds on the loader’s frame.

- Inspect the body and bucket for any signs of impact or damage.

2. Engine:

- Start the engine and check for unusual noises, smoke, or vibrations.

- Inspect for oil leaks around the engine and related components.

- Check the air filter for cleanliness.

- Check for extended blow-by and pressure in the cooling system.

3. Transmission and Drive train:

- Test the transmission through all gears, both forward and reverse.

- Check for any unusual noises or vibrations during operation.

- Inspect the condition of the drive shafts and universal joints.

- Test the transmission in manual and automatic mode.

4. Hydraulic Systems:

- Test all hydraulic functions, including the lifting and tilting of the bucket or attachment.

- Look for leaks in hydraulic hoses, fittings, and connections.

- Check the hydraulic fluid level and condition.

- Test the torque stall speed or the hydrostatic drive with appropriate tests.

5. Bucket or Attachment:

- Inspect the bucket or attachment for signs of damage, cracks, or excessive wear.

- Check for smooth and precise operation of the bucket control.

- Ensure there is no play in the pivot points.

6. Tires:

- Inspect the condition of the tires for wear, damage, or uneven tread wear.

- Check tire pressure and ensure it meets the manufacturer’s specifications.

- Look for any signs of bulges or cuts.

- Measure the tire tread for remaining life time estimation.

7. Brake System:

- Check the condition of the brakes, including pads, drums and discs.

- Test the brake pedal for responsiveness.

- Inspect brake lines for leaks or damage.

8. Steering System:

- Test the steering for smooth operation.

- Check for any unusual noises or play in the steering components.

9. Chassis:

- Inspect the frame and chassis for cracks or signs of stress.

- Check for any loose or missing bolts in the frame.

10. Cab and Controls:

- Inspect the condition of the cab, looking for damage, rust, or water leaks.

- Test all controls for smooth operation, including the steering and loader functions.

- Check the condition of the operator’s seat, seatbelt, and visibility.

11. Electrical System:

- Inspect the battery for age and condition.

- Test all lights, indicators, and gauges.

- Check the condition of wiring and connectors.

12. Fluids and Lubricants:

- Check the levels of engine oil, transmission fluid, hydraulic fluid, and coolant.

- Inspect the color and condition of these fluids.

- Look for any signs of contamination in the fluids.

13. Documentation:

- Request and review maintenance records, service history, and any available inspection reports.

- Check the serial number and verify it against the provided documentation.

14. Operational Test:

- Take the wheel loader for a test drive to evaluate its performance.

- Pay attention to how it handles, accelerates, and brakes.

Always consider having a qualified Mevas-Technician or mechanic with experience in heavy equipment perform a thorough inspection if you are not familiar with the specific requirements of wheel loaders. Additionally, consulting the manufacturer’s guidelines and specifications for the particular model of the wheel loader is essential for a comprehensive assessment.

Liste de contrôle pour une chargeuse sur pneu

Tu trouveras ici un exemple de liste de contrôle pour une chargeuse pneu. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.