Inspection form for tracked / crawler excavators

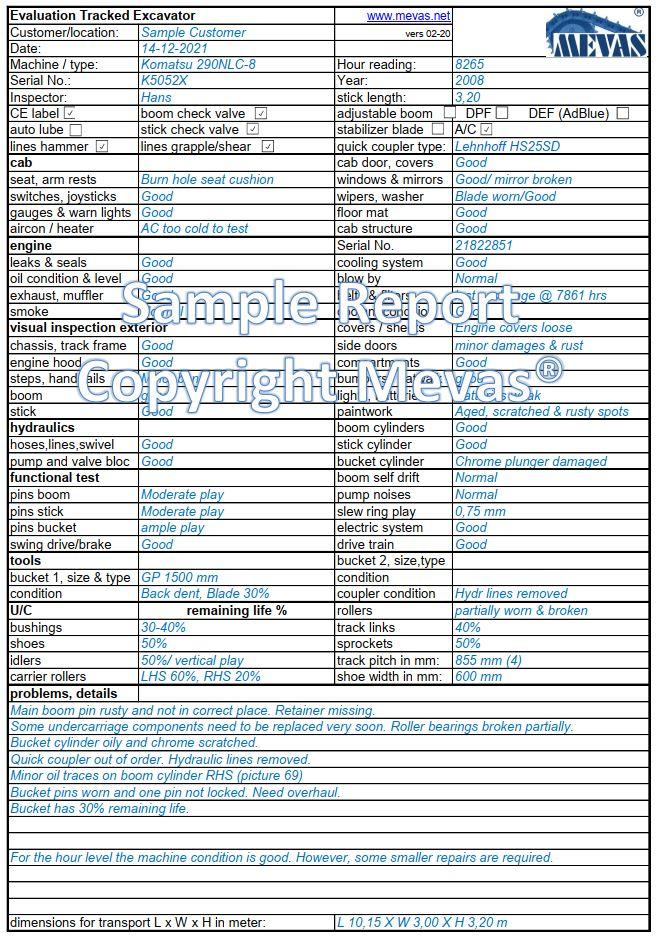

A Mevas inspection checklist contains around 60 items that the engineer will check during an inspection. These details are provided to the recipient:

- Basic Machine information (year, hours, serial numbers, features)

- Operator Station details and condition

- Engine information, condition and performance, cooling system

- Condition of Exterior (chassis, sheet metal, paint)

- Condition of hydraulic system (pump, performance, hydraulic lines and cylinders)

- Condition of Undercarriage (tracks, chains, sprockets)

- Functional test and performance test

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

TA1 for Track excavator

The above-described level of inspection is called TA-1. It is based on international standards for machinery inspections. We aim to keep reports concise and printable on one page.

Which extras can you order with a TA1 for hydraulic excavators?

To learn more about the condition without opening the engine or hydraulic pump, it is recommended that oil and coolant samples are taken. These samples are analysed in a certified German laboratory. The presence of copper, aluminium, sulphur or silicon can provide information about the condition of components. The cost for this analysis is € 140 per fluid.

Another option would be to perform a pressure test on the hydraulic system. We can perform this test, and if you obtain the reference information from the machine’s manufacturer, you can check whether the values are within the expected range. This test costs € 80.

Last but not least we can offer a measurement of undercarriage components. This service costs € 120 for one excavator.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 80-100 pictures and in some cases with a short video. In case of interest it is possible to see an excavator report in detail on our Google-Drive folder.

Video about excavator inspection by Mevas

For some kind of machines we made a video about the inspection process. For an excavator inspection a video it is available on the Mevas YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What elements should a proper checklist for inspecting a used excavator contain?

Inspecting a used excavator is crucial to ensure that it is in good working condition and meets your requirements. Here’s a checklist to guide you through the inspection process:

1. Overall Inspection:

- Check for visible signs of damage, cracks, or welds on the frame.

- Look for any signs of oil or fluid leaks underneath the machine.

- Inspect the condition of the paint for rust, peeling, or excessive wear.

2. Undercarriage:

- Check the tracks or tires for wear, damage, or uneven tread wear.

- Inspect the rollers, idlers, and sprockets for excessive wear.

- Measure the track tension and check for any loose or damaged components.

3. Engine:

- Start the engine and check for unusual noises, smoke, or vibrations.

- Inspect for oil leaks around the engine and related components.

- Check the air filter for cleanliness.

4. Hydraulics:

- Test all hydraulic functions, including boom, arm, and bucket movements.

- Look for leaks in hydraulic hoses, fittings, and connections.

- Check the hydraulic fluid level and condition.

5. Boom, Stick and Bucket:

- Inspect the boom, stick and bucket for signs of damage, cracks, or excessive wear.

- Check for smooth and precise operation of these components.

- Ensure there is no play in the pivot points.

6. Swing Drive & Gear:

- Test the swing functionality for smooth operation.

- Check for any unusual noises during the rotation.

- Inspect the slew ring for wear or damage. Measure the play.

7. Cab and Controls:

- Inspect the condition of the cab, looking for damage, rust, or water leaks.

- Test all controls for smooth operation.

- Check the condition of the operator’s seat, seatbelt, and visibility.

8. Tracks/Undercarriage:

- Inspect the condition of tracks for any signs of damage or excessive wear.

- Check the tension of the tracks.

- Inspect the rollers, idlers, and sprockets for wear.

9. Electrical System:

- Inspect the battery for age and condition.

- Test all lights, indicators, and gauges.

- Check the condition of wiring and connectors.

10. Fluids and Lubricants:

- Check the levels of engine oil, hydraulic fluid, and coolant.

- Inspect the color and condition of these fluids.

- Look for any signs of contamination in the fluids.

11. Documentation:

- Request and review maintenance records, service history, and any available inspection reports.

- Check the serial number and verify it against the provided documentation.

12. Operational Test:

- Take the excavator for a test drive to evaluate its performance.

- Test the functionality of all components in real-world conditions.

Always consider having a qualified mechanic or a Mevas-Technician perform a thorough inspection if you are not experienced in evaluating heavy equipment. Additionally, consulting the manufacturer’s guidelines and specifications for the specific model of the excavator is essential for a comprehensive assessment. More info about used excavator inspection can be read in our article about excavator inspections.

Liste de contrôle pour une pelle chenilles

Tu trouveras ici un exemple de liste de contrôle pour une pelle hydraulique sur chenilles. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.