Excavator inspection checklist and what to approve

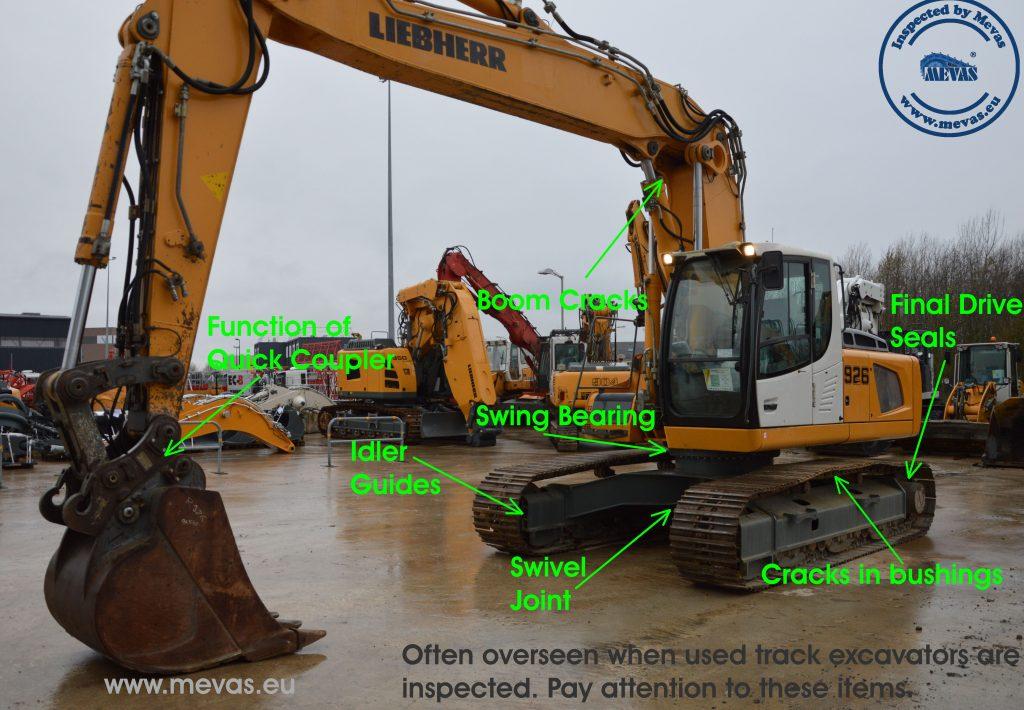

Inspection of used excavators is not everyone’s daily business. Less experienced technician sometimes miss important items such as a leaking swivel, play in swing bearing, cracks in boom or worn idler guides. A good strategy before you inspect used equipment is using a detailed inspection checklist. For excavators or any other machinery you need to check or get checked. So you make sure to check every component and make sure no important item will be missed. Here you can find a sample for such an checklist.

Mevas excavator inspection checklist

If no own engineer is available for the inspection – talk to Mevas. We have local technicians in more than 22 countries and can access other places easily.

Which items should be inspected during an excavator inspection?

During inspection of a used track excavator, the following items should be inspected:

- Engine and transmission (wheel excavator)

- Hydraulic system and pumps, pump drive

- Undercarriage components and tires on wheel excavators

- Cab and controls

- Boom and stick

- Bucket and teeth

- Electrical system, ECM, ECU, monitoring system and alert lights

- Swing bearing and swing gear

It is important to inspect each of these items thoroughly, as they are critical components that affect the excavator’s performance and overall condition. Some of these items are more critical than others, such as the engine and hydraulic system, which directly impact the excavator’s power and operation, while others, such as the cab and controls, affect the operator’s comfort and safety. The importance of each item will depend on the specific use case and requirements for the machine.

What are the important assemblies of a crawler excavator?

A crawler excavator is a complex piece of heavy machinery designed for digging, excavation, and earthmoving tasks. It consists of several important assemblies and components that work together to perform various functions. Here are the key assemblies of a typical crawler excavator:

Main items

- Crawler Tracks: The crawler tracks are a critical component that allows the excavator to move on various terrains. They consist of a system of tracks or chains, sprockets, and rollers.

- Undercarriage: The undercarriage includes the lower frame of the excavator and houses the crawler tracks, rollers, and sprockets. It provides stability and mobility to the machine.

- Upper Structure: The upper structure houses the engine, operator’s cabin, and hydraulic systems. It is the part of the excavator that rotates and pivots on the undercarriage.

- Engine: Crawler excavators typically use diesel engines for their high torque and reliability.

- Hydraulic System: The hydraulic system powers the various functions of the excavator, including the boom, arm, bucket, and other attachments. It controls the flow and pressure of hydraulic fluid to operate the machine’s movements.

- Boom: The boom is an extendable arm that is attached to the upper structure and is used for reaching and lifting.

- Arm: The arm, also known as the dipper arm or stick, is connected to the boom and can be extended and retracted.

- Bucket: The bucket is attached to the arm and is used for digging, scooping, and loading materials. Buckets come in various sizes and configurations for different tasks.

- Operator’s Cabin: The operator’s cabin is where the machine is controlled. It houses the controls, displays, and a comfortable seat for the operator.

- Counterweight: The counterweight is a heavy weight placed at the rear of the excavator to balance the weight of the front-end attachments and prevent the machine from tipping over.

- Hydraulic Cylinders: These are responsible for moving and controlling the boom, arm, and bucket. They extend and retract to perform digging and lifting operations.

- Control System: The control system includes joysticks, pedals, and buttons in the operator’s cabin that allow the operator to control the various movements and functions of the excavator.

- Attachments: Crawler excavators can be equipped with various attachments such as grapples, breakers, thumbs, and more, depending on the specific job requirements.

Summary

These are the fundamental assemblies and components of a crawler excavator. The combination of these elements enables the machine to perform a wide range of excavation and construction tasks with precision and efficiency.

What is different between a tracked and a wheel excavator?

A wheel excavator, as the name suggests, differs from a crawler excavator primarily in its mode of mobility. While the basic functions and components are similar, the wheel excavator is mounted on wheels instead of crawler tracks. Here are the key differences between a wheel excavator and a crawler excavator:

Mobility:

- Crawler Excavator: It is equipped with crawler tracks that provide excellent stability and traction on uneven or soft terrain. Crawler excavators are often used in rough and challenging terrains, including construction sites, mines, and forestry operations.

- Wheel Excavator: Wheel excavators are mounted on wheels, similar to a typical vehicle. They are more suitable for operating on roads or other solid surfaces. Wheel excavators offer greater speed and mobility on paved or firm ground, making them well-suited for urban construction or roadwork.

Undercarriage:

- Crawler Excavator: It has a heavy undercarriage that houses the crawler tracks, rollers, and sprockets, which provide stability and distribute the machine’s weight evenly over a larger surface area.

- Wheel Excavator: The undercarriage of a wheel excavator consists of wheels and tires, which are more similar to those of a truck or a vehicle. This undercarriage is designed for improved road travel.

Ground Pressure:

- Crawler Excavator: Crawler excavators have a lower ground pressure due to the larger surface area of their tracks, making them suitable for work in soft or sensitive terrains without causing as much ground damage.

- Wheel Excavator: Wheel excavators typically have a higher ground pressure compared to crawler excavators. This can make them less suitable for soft or sensitive ground conditions.

Versatility:

- Crawler Excavator: Crawler excavators are known for their versatility in off-road applications and rough terrains. They can handle a wide range of tasks, from digging and lifting to forestry work.

- Wheel Excavator: Wheel excavators are more specialized for tasks that involve frequent movement between job sites on solid surfaces. They are often used for urban construction, road maintenance, and tasks that require frequent relocation.

Speed and Travel:

- Crawler Excavator: While crawler excavators are slower when it comes to road travel, they excel in off-road mobility and stability.

- Wheel Excavator: Wheel excavators can travel at higher speeds on roads and are better suited for tasks that involve longer travel distances between worksites.

In summary, the main difference between a wheel excavator and a crawler excavator is their mobility and undercarriage. Wheel excavators are designed for jobs that require frequent movement on roads and solid surfaces, while crawler excavators excel in off-road applications and challenging terrains. The choice between the two types of excavators depends on the specific job requirements and operating conditions.

Have a professional service inspection excavators before you buy

Protect your investment and buy with confidence—MEVAS inspection experts uncover hidden defects, prevent costly surprises, and provide objective condition reports for any used machine. Gain negotiation power, extend equipment lifespan, and ensure safe operations by choosing independent, professional machine inspections before purchase.