With a Mevas Mobile crane inspection you will receive a detailed report

Are you looking for a used crane in Europe and want to ensure your investment is a sound one? It is crucial to thoroughly check the crane’s current condition and identify any potential weaknesses before making a purchase. This is where Mevas’ experts can help. As an independent service provider, Mevas’s experienced technicians regularly carry out thorough inspections of mobile cranes and provide detailed assessments.

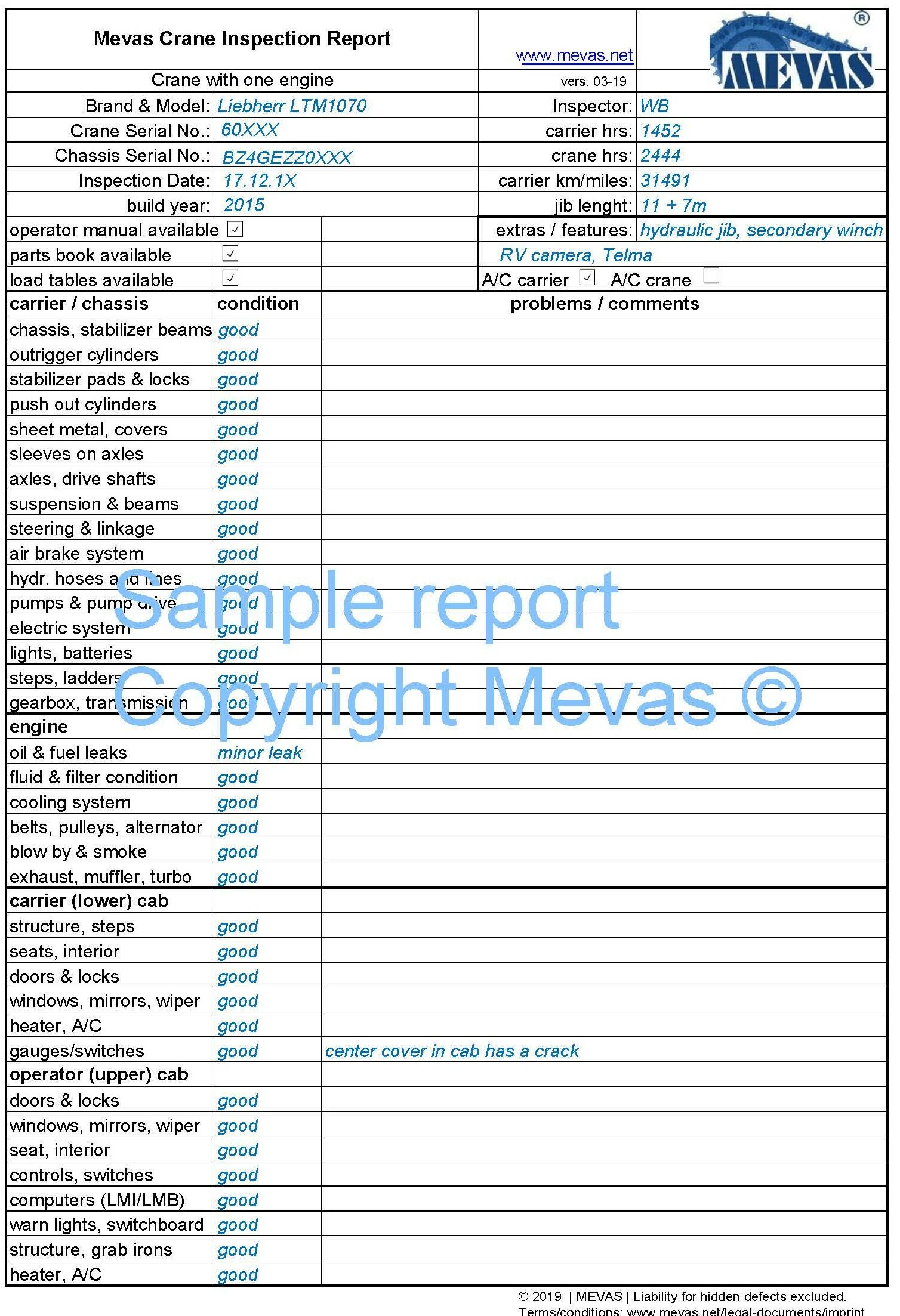

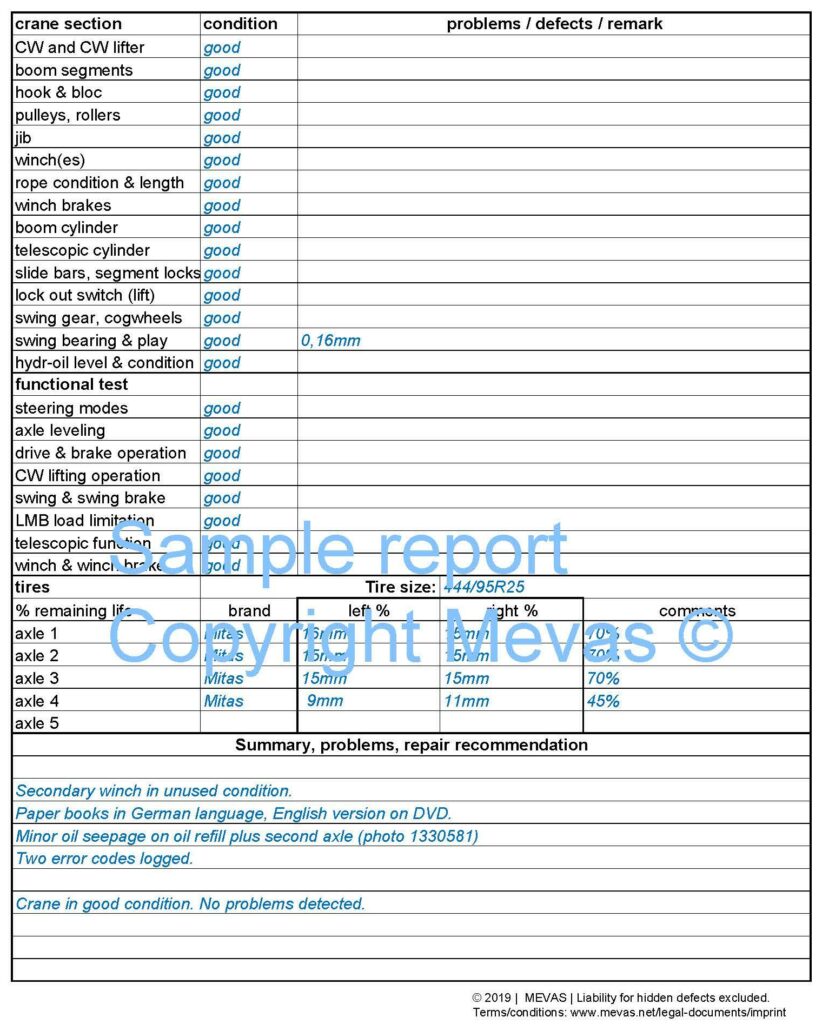

120-points checklist for crane inspection

Below, you can see which items and functions are checked during a used crane inspection. The Mevas crane inspector works through the inspection report step by step, making a comment for each item. Together with the crane operator, they perform some tests:

- Crane configuration and additional Features

- Condition of the Carrier and Chassis

- Engine & Transmission information and condition

- Condition of the lower and the upper Cab (structure, windows, controls)

- Condition of the Crane section (boom segments, pulleys, jib, rob, winch)

- Functional test (steering modes, axle leveling, telescopic function, winch)

- Load test if possible on site and measurement of swing bearing play

- Tire condition, drive test for transmission & brake system

- Comments and recommendation for repairs

See a sample of a report below. Please note, the form is under Mevas copyright.

What extras can you order?

On request we can offer additional specific testing and inspection as per your requirements. You can define load tests and other details.

If you have questions about the crane inspection service please contact the team. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each crane inspection comes along with 70-100 pictures and a video. In case of interest it is possible to see a crane inspection report in detail on our Google-Drive folder.

Video about crane inspection by Mevas

For some kind of machines we made a video about the inspection process. For a mobile crane inspection a video it is available on our YouTube-Channel.

A function test is an important part of every crane inspection. We liaise with the seller and ask them to provide a crane driver, since this is the only way to ensure that the crane is functioning reliably. However, the performance of a crane inspection always depends on the situation on site. In some cases, cranes cannot be ballasted or fully extended due to local restrictions.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

What you should check during a mobile crane inspection

1. Visual Inspection

- Structural Integrity: Look for cracks, corrosion, or any signs of damage on the boom, jib, and superstructure.

- Welds and Joints: Check for cracks, poor repairs, or rust around welds and joints.

- Painting: Assess the condition of the paintwork for rust spots or flaking that could indicate underlying issues.

- Tires: Check the condition and wear of all tires.

2. Mechanical Components

- Engine: Inspect the engine for leaks, unusual noises, and ensure it starts easily. Check the condition of belts, hoses and filters.

- Hydraulic System: Watch out for leaks, wear in hoses, and ensure hydraulic cylinders and pumps are functioning properly.

- Transmission and Drive train: Verify smooth operation and check for leaks or abnormal noise.

3. Functional Test

- Controls: Test all control functions for responsiveness and accuracy.

- Safety Systems: Ensure all safety features such as limit switches, load moment indicators and emergency stop functions are operational.

- Brakes: Test the brakes for effectiveness and check the condition of brake pads and lines.

4. Load Handling Components

- Hooks and Chains: Inspect for wear, deformation, and proper operation.

- Wire Ropes: Check for fraying, corrosion, and proper spooling on the drum.

- Sheaves and Pulleys: Ensure they are in good condition without cracks or excessive wear.

5. Electrical System

- Wiring: Inspect for frayed wires, loose connections and proper insulation.

- Lights and Indicators: Ensure all lights and indicators are working.

- Control Panels: Check for any signs of wear, damage, or malfunction in the control panels.

6. Boom and Jib

- Telescoping Mechanism: Test the telescoping mechanism for smooth operation.

- Boom Sections: Inspect all sections of the boom for cracks, bends, or other signs of damage.

7. Stability and Balance

- Outriggers and Stabilizers: Check the condition and operation of outriggers and stabilizers. Ensure they extend and retract smoothly and provide stable support.

8. Accessories and Attachments

- Additional Equipment: Inspect any additional attachments or accessories for their condition and proper operation.

9. Documentation

- Maintenance Records: Review maintenance logs for regular servicing and any significant repairs.

- Inspection Certificates: Verify that the crane has been regularly inspected by qualified professionals.

- Operational History: Check the crane’s operational history for any previous accidents or major repairs.

You need help?

While you can perform a basic inspection yourself, it’s highly recommended to engage a professional inspector. Our technicians can help and identify any issues that might not be apparent to an untrained eye. Get in touch with us today.

Crane-inspectors.com

We have a specific website for all info about inspection of used crawler and mobile cranes. Visit www.crane-inspectors.com for more info

Other categories what we inspect:

All Terrain Cranes, Aerial Platform Lift Trucks, Boom Truck Cranes, Digger Derricks, Crawler Cranes, Truck-Mounted, Lattice Boom, Telescopic Boom, Gantry Cranes / Overhead Cranes, Bridge Cranes, Container / Stacking Cranes, Rough Terrain Cranes, Harbor / Marine / Barge Cranes, Knuckle Boom Cranes, Pile Driving Cranes, Railroad Cranes, Tower Cranes, City Cranes, Reach Stackers, Harbor Cranes

Liste de contrôle pour une grue mobile ou grue sur chenilles

Tu trouveras ici un exemple de liste de contrôle pour une grue mobile ou grue sur chenilles. Cette fiche d’inspection est utilisée pour inspecter les machines d’occasion. 60 points sont contrôlés et l’inspecteur note toutes ses observations et décrit les défauts constatés. Tu trouveras une liste de tous les formulaires disponibles ICI. La version de la liste de contrôle présentée ici n’est pas la version la plus récente. Nos rapports d’inspection sont régulièrement mis à jour.