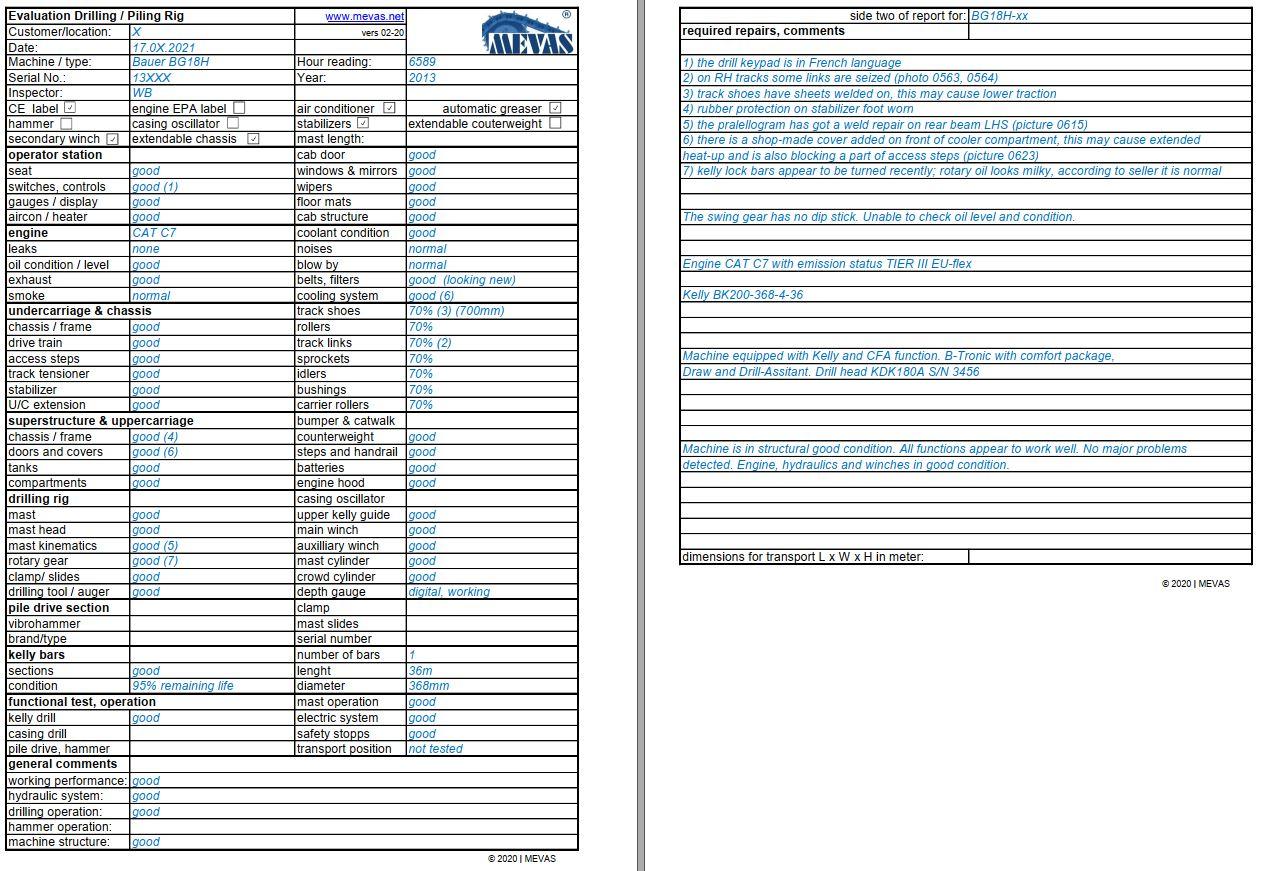

Mevas Checklist for inspection of a pile driver or a drilling rig

If you order an inspection of an used pile driver, a drilling rig or another machine for civil engineering you will receive a detailed checklist with all related machine items.

- Basic Machine information (attachments, features, CE labeling, serial No., working hours etc.)

- Operator Station details and condition, controls and monitoring

- Info about features (CFA, Augers, Drill Modes, diaphragm wall, trenching, desanding)

- Engine information and condition

- Condition of Exterior (chassis, sheet metal, mast, drilling tool)

- Condition of hydraulic system (pump, drill head, hydraulic lines and cylinders)

- Condition of Undercarriage (tracks, chains, sprockets)

- Functional test as far as possible

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about the service please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 70-100 pictures and in some cases with a short video. In case of interest it is possible to see a pile driver report in detail on our Google-Drive folder.

Video about machinery inspections by Mevas

For some kind of machines we made a video about the inspection process. Currently we don’t have a video available for a pile driver, but you are welcome to find out more about our services on our YouTube channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

Which components should be checked during inspection of an used engineering drill rig?

Inspecting an used engineering drill rig is crucial to ensure that it is in good working condition and meets safety standards. Here are some key components that should be checked during the inspection:

- Frame and Structure:

- Inspect the overall frame and structure for signs of damage, corrosion, or structural weaknesses.

- Check for any cracks or weld failures in the frame.

2. Power System:

- Examine the engine, motor, or power source for leaks, unusual noises, or excessive smoke.

- Check the engine hours and compare them to the maintenance records.

3. Drilling Mechanism:

- Inspect the drilling components, including the drill head, drill bit and drill pipe, for wear and damage.

- Examine for proper alignment and functioning of the drilling mechanism.

4. Hydraulic System

- Check hydraulic hoses and fittings for leaks, wear and proper connections.

- Test the hydraulic system for smooth operation and responsiveness.

5. Control System

- Test all controls and gauges to ensure they are functioning properly.

- Inspect the control panel for damage or signs of wear.

6. Mast and Boom

- Inspect the mast and boom for any signs of bending, cracking or other structural issues.

- Check the cables and pulley systems for wear and proper tension.

7. Stabilizers and Outriggers

- Ensure that stabilizers and outriggers deploy and retract smoothly.

- Check for damage or signs of wear on the stabilizing components.

8. Cooling System

- Safety Features:

- Verify the presence and functionality of safety features such as emergency stops, interlocks, and warning systems.

- Ensure that safety decals and instructions are in place and legible.

- Documentation:

- Review the maintenance records, service history, and any available inspection reports.

- Check for compliance with local regulations and standards.

- Overall Appearance:

- Assess the general cleanliness and appearance of the drill rig, which can provide insights into the level of maintenance and care it has received.

It’s advisable to involve a qualified MEVAS technician or engineer with experience in drill rigs for a thorough inspection. Additionally, consider conducting operational tests to ensure the rig performs as expected in various drilling conditions. Always follow safety protocols and guidelines during the inspection process.