Where can I find a professional inspector?

Mevas is the leading provider of inspections of used machinery around the world. Based in Germany, the company has a global network of inspectors. There may be others inspection more machines. But this does not always happen for the benefit of a potential buyer.

Allow us to introduce ourselves briefly: Mevas has been testing the condition of heavy machinery for over 19 years. The idea came about when the company owner realised, in his previous job, that the used machines he was buying were often in worse condition than stated by the seller.

This inspired the idea of carefully checking machines before purchasing them. We now offer this service to an expanding client base from all over the world. Similarly, we offer this service to sellers to help them sell their machines by providing an inspection by an independent third party.

Which used heavy machines can be inspected?

Mevas inspectors can perform inspections for:

- Excavators (track excavators, mobile excavators, min diggers, quarry shovels)

- Bulldozers and Tracked Loaders

- Loaders (Wheel Loaders, Skid Steer Loaders, Backhoe Loaders)

- Graders and Wheel dozers

- Dump Trucks

- Compactors for Soil and Waste

- Rollers (Vibratory Rollers, Pneumatic Rollers, Tandem Rollers)

- Scrapers and Bucket Dozers

- Off-Highway Trucks and on the Road Trucks

- Drilling Rigs, Pile Drivers, Surface Drills, Civil Engineering Machinery

- Concrete Mixers, concrete pumps and readymix trucks

- Pavers for Asphalt and Concrete

- Telehandlers, Telescopic Forklifts

- Trenchers, Milling Machines, Reclaimer and Recycler

- Reach Stackers and Container Handlers

- Agricultural Tractors, Combines, Harvester

What does an Mevas inspection report contain?

We create a structured inspection report for every type of used construction machine or vehicle.

At the beginning, the inspector records the machine’s equipment and configuration. This includes checking whether the unit has air conditioning, additional hydraulic lines, a dozer blade (on excavators), a CE certificate, or a quick coupler. Hour meter reading is taken.

The actual inspection then starts. First, the cab is examined in detail: seat condition, switches, display instruments, air conditioning, windows, mirrors, and windscreen wipers are checked carefully.

Next comes the engine inspection. After verifying the operating fluids such as coolant and oil condition, the engine is started. The inspector checks for unusual smoke, abnormal noises, or other signs of increased wear.

Following the engine, the machine’s external components are examined. This includes the frame, boom or lift arm, all doors and hatches, storage compartments, lighting, and paintwork.

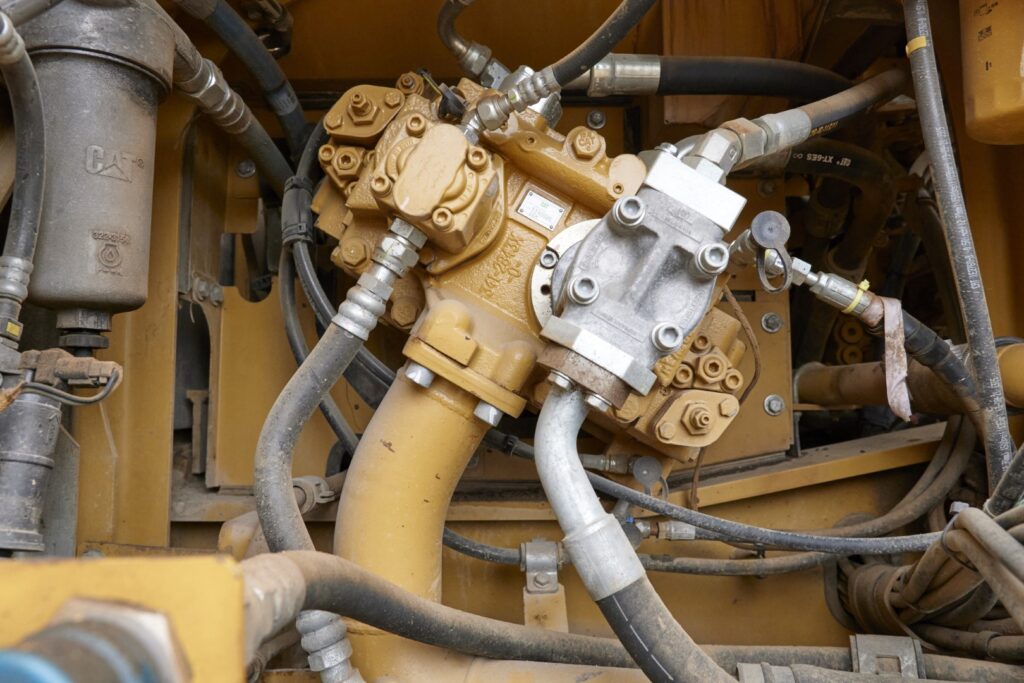

The inspection then focuses on the hydraulic system. Hoses, cylinders, and hydraulic pumps are checked for leaks, while the hydraulic pump and valve block are evaluated for noises or pressure issues.

Once these checks are complete, the functional test begins. Here, the inspector observes:

- Play in joints and linkages

- Proper drive performance

- Unusual noises

- Whether all functions operate normally

Depending on the type of machine, relevant attachments such as buckets or shovels are also inspected and their details recorded.

Finally, the tyres or undercarriage are checked for wear and assessed in detail. In the last section of the inspection report, any additional remarks are documented. The inspector concludes with a summary comment on the machine’s overall condition, and in most reports, the transport dimensions are also included.

This list is not exhaustive, but covers the most commonly used earthmoving and construction machines. The specific machines used for a construction project depends on the type and scope of the work, as well as the local conditions and regulations.