Who Can Inspect Used Civil Engineering Equipment?

One of the most important steps before purchasing or reselling heavy machinery is a professional inspection of used civil engineering equipment. These machines are highly specialized, technically complex, and often customized for specific construction projects. Without expert evaluation, buyers and sellers may overlook hidden defects, safety risks, or operational inefficiencies that could result in costly repairs or downtime later.

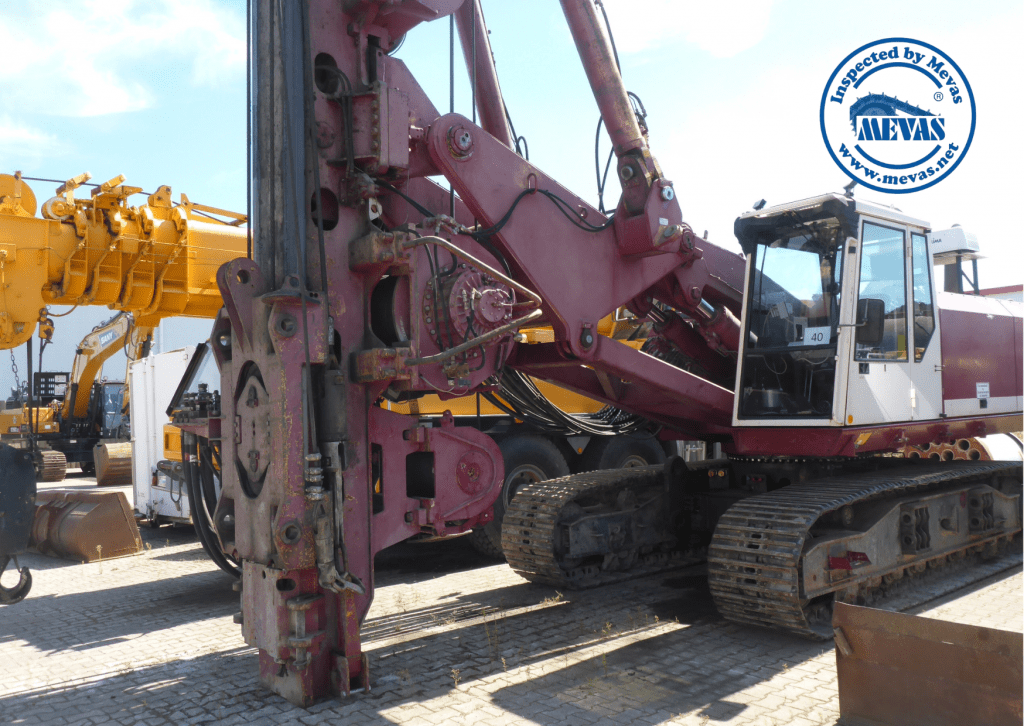

Our team is specialized in independent inspections and technical evaluations of used civil engineering machines and any other kind of heavy equipment. We understand that every piece of equipment has unique specifications and must be carefully assessed to ensure it meets industry standards and project requirements. Whether you are an equipment dealer, contractor, or international buyer, we can provide reliable on-site assessments and detailed inspection reports.

We regularly inspect a wide range of machinery, including but not limited to:

- Drill rigs and piling machinery

- Desanding machines and slurry treatment plants

- Vibrators and hydraulic vibration hammers

- Leaders, telescopic leaders, and RTG equipment

- Diesel impact hammers and hydraulic hammers

- Duty-cycle cranes, grab systems, and diaphragm wall grabs

Each category requires a different set of technical knowledge, from evaluating hydraulic systems and wear conditions to verifying compliance with safety regulations. For example, specialized components like the Kelly bar—a critical tool used in rotary drilling rigs—need careful attention during inspection to ensure safe and efficient performance.

If you do not have a qualified service technician available, or if the machine is located abroad and difficult to reach, our inspection service can save you time and money. We can provide detailed condition reports, photo documentation, and professional advice to help you make confident decisions when investing in used construction machinery.

👉 Have you worked with equipment like rotary drilling rigs, diaphragm wall grabs, or Kelly bars before? Share your experience in the comments—we’d love to hear from you!

What kind of heavy civil engineering equipment is known and what is it used for?

Heavy foundation equipment is specialized machinery used in the construction of foundations for buildings, bridges, and other structures. These machines are designed to handle the challenges of excavating, drilling, and preparing the ground to support the weight and stability of the structure. Here are some common types of heavy foundation equipment and their primary uses:

- Pile Drivers: Pile drivers are used to install piles (vertical structural supports) into the ground. These piles can be made of concrete, steel, or wood and serve as the foundation for structures. Pile drivers use hydraulic or diesel hammers to drive piles into the soil.

- Drilling Rigs: Drilling rigs are used to bore deep holes into the ground for various foundation types, including drilled piers, caissons, and micropiles. They are commonly used in projects requiring deep foundation solutions with CFA. Well known are brands such as Bauer, Casagrande or Soilmec.

- Vibrodrivers: Vibrodrivers use vibration and force to drive sheet piles or steel H-beams into the ground. They are particularly useful for creating retaining walls and other foundation support structures.

- Cranes: Cranes are used to lift and place heavy elements of a foundation, such as precast concrete sections or steel beams. They are also employed for positioning drilling rigs and piling equipment. Cranes are often used for diaphragm wall foundation.

- Compactors: Compactors are used to compact the soil or fill material, ensuring proper density and support for the foundation. They come in various forms, including plate compactors and roller compactors.

- Concrete Mixers and Batch Plants: These machines are used to mix and batch concrete for various foundation types, including footings, slabs, and mat foundations.

- Foundation Drills: These drills are specifically designed for creating holes and bores in the ground for piles or caissons. They can include rotary drills and auger drills.

- Soil Stabilizers: Soil stabilizers are used to improve the properties of the soil by mixing it with binding agents. This is essential for creating a solid foundation in areas with challenging soil conditions.

- Tunnelling Equipment: In the case of tunnel foundations, specialized equipment such as tunnel boring machines (TBMs) are used to excavate tunnels in underground construction projects.

The choice of foundation equipment depends on the specific requirements of the project, the type of foundation needed, and the geological and environmental conditions of the site. Proper foundation preparation is crucial to ensure the stability and longevity of the structure being built. We even inspect workshops in construction companies including the overhead cranes.