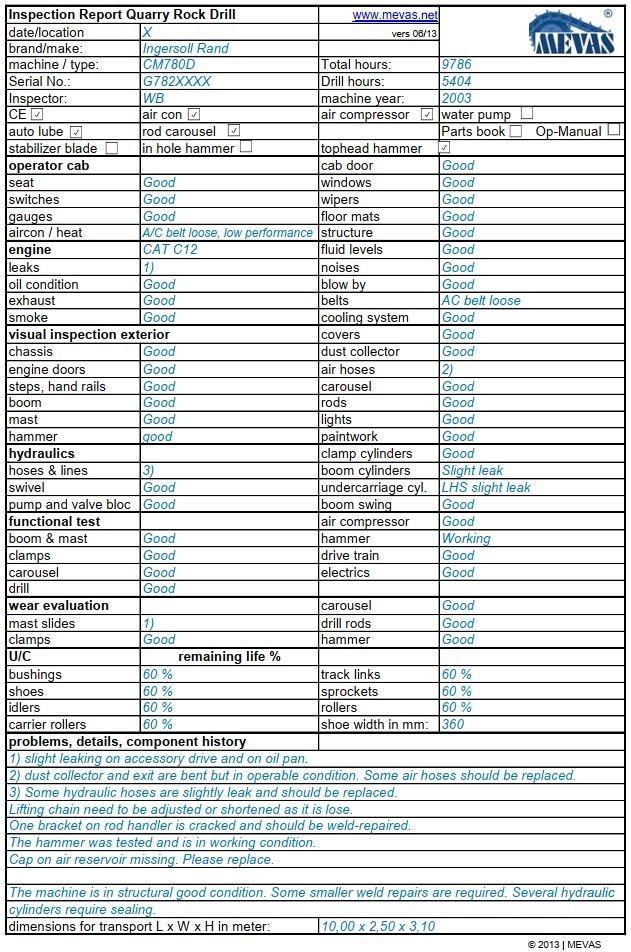

Inspection checklist for used quarry or surface blasthole rock drill

- Basic Machine information (hammer type, carousel type, serial No., working hours)

- Operator Station details and condition

- Engine information and condition

- Condition of Exterior (chassis, sheet metal, paint)

- Hydraulic system condition (pump, performance, hydraulic lines and cylinders)

- Remaining life of the Undercarriage (tracks, chains, sprockets)

- Condition boom and mast, carousel and drilling unit

- Functional test

- Diameter and number of drill rods

- Comments and recommendation for repairs

- Transport dimensions

See a sample of a report below. On request we can send a PDF-version of such a report.

What extras can you order?

Once you receive an offer it will be always for a basic walk-around with functional check. This level is called TA1. On our Checklist-Options page you can find additional services which you can order.

If you have questions about surface drilling equipment inspection please contact the team by Whatsapp or by phone +493520639150. We are happy to answer in detail.

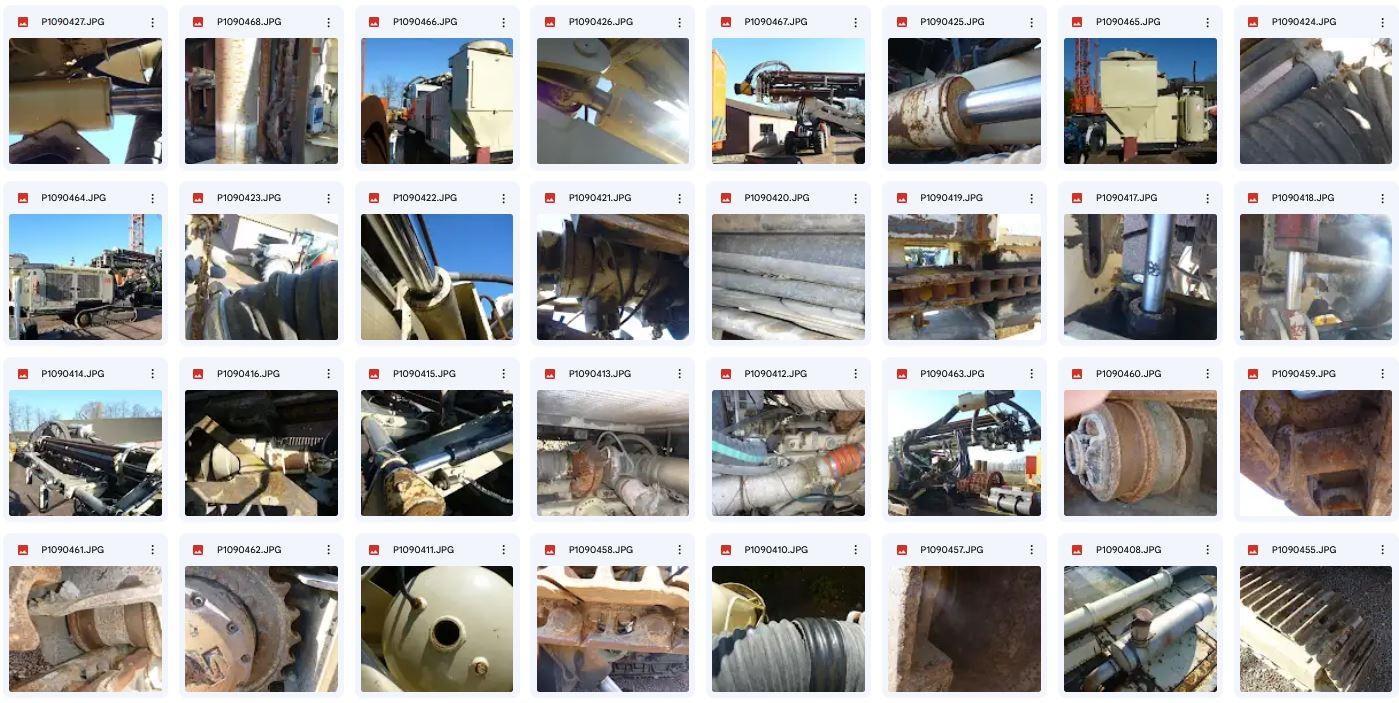

Pictures and video coming with a Mevas-Report

Each machine inspection comes along with 50-80 pictures and in some cases with a short video. In case of interest it is possible to see an rock drill report in detail on our Google-Drive folder.

Video about the inspection process by Mevas

For some kind of machines we made a video about the inspection process. Check out our YouTube-Channel.

Other sample reports heavy machinery

Visit our overview for other sample inspection checklists for heavy machinery.

Keep in mind: Report forms are our legal property and copying is a violation of our copyright.

Which items need special attention during inspection of an used blast hole rock-drill for quarry use?

Inspecting an used blast hole rock drill for quarry use is crucial to ensure its safety, efficiency and the work performance. Here are some key items that need special attention during the inspection:

- Physical Condition:

- Examine the overall physical condition of the rock drill. Look for signs of wear, damage or corrosion on the exterior components.

- Check for any visible cracks or weld repairs, especially in critical areas such as the drill frame, hammer, dust removal system and housing.

- Drill Steel and Consumables:

- Inspect the drill steel for signs of wear, bending, or damage. Ensure that the threads are in good condition. Check the rods and the feeder including carousel.

- Check the condition of drill bits and other consumables. Worn-out or damaged bits can affect drilling efficiency.

- Hydraulic System:

- Check for leaks in the hydraulic system. Inspect hoses, fittings and seals for signs of damage or wear. Check the hose package to mast and drilling unit.

- Test the hydraulic pressure to ensure it meets the manufacturer’s specifications.

- Rotation Mechanism:

- Inspect the rotation mechanism for smooth operation. Check for any unusual noises or vibrations during rotation.

- Examine the condition of bearings and gears in the rotation system.

- Feed System:

- Evaluate the feed system for proper functionality. Ensure that it moves smoothly and without hesitation.

- Check for wear on the feed components, such as slides, guides, clamps and bushings.

- Control Systems:

- Test and inspect the control systems, including the control panel and joystick, for proper functioning.

- Check for any loose or damaged wiring, and ensure that all safety features are operational.

- Carrier Vehicle Integration:

- If the rock drill is mounted on a carrier vehicle, inspect the integration points. Check for proper alignment and mounting stability.

- Ensure that any components connecting the drill to the carrier, such as bolts and brackets, are secure and in good condition. Check undercarriage and chassis for damage and cracks.

- Documentation:

- Verify the availability of the user manual, maintenance records, and any other relevant documentation. This can provide valuable insights into the drill’s history and maintenance. Get a download from engine ECU to verify working hours.

- Fluids and Lubricants:

- Check the levels and condition of fluids, such as hydraulic oil and lubricants. Ensure that they are at the recommended levels and free from contaminants.

- Safety Features:

- Verify that all safety features, such as emergency stops and safety guards, are in place and functional.

- Inspect warning labels and signage for clarity and completeness.

- Testing:

- Conduct a functional test of the rock drill under load to ensure it performs as expected.

- Observe the drill in action to identify any irregularities in operation.

It’s important to note that this list is not exhaustive, and the specific inspection requirements may vary depending on the make and model of the rock drill. Always refer to the manufacturer’s guidelines and specifications for a comprehensive inspection checklist tailored to your equipment. If you’re not familiar with the inspection process, consider involving a qualified technician or inspector to ensure a thorough evaluation.

Inspection of Civil Engineering Drills

Mevas has a couple of experienced technician who not only know about blast hole drilling equipment. During the years we have inspected also many used drills for foundations. Mevas inspects regularly the so-called civil engineering drills and piling machines.