What to Inspect and How during an Excavator Inspection

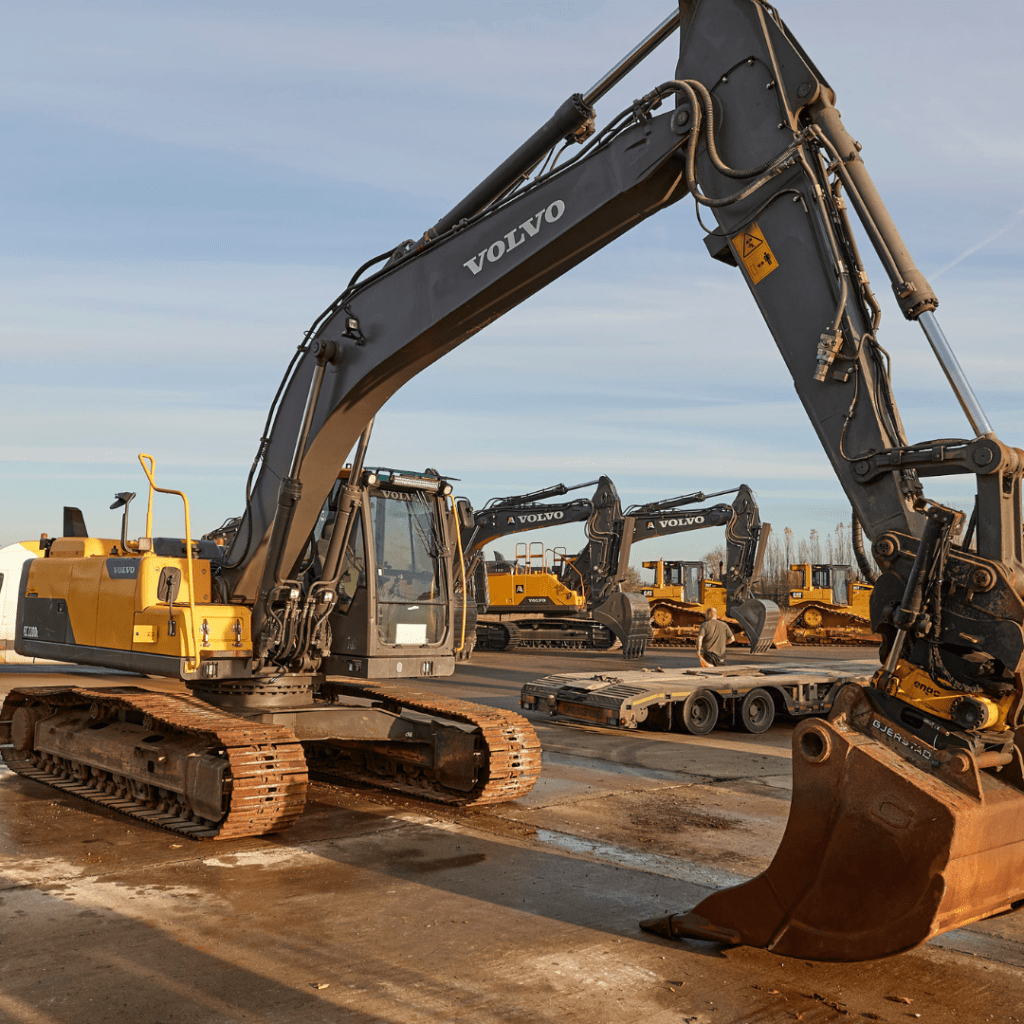

When purchasing a used excavator, conducting a thorough technical inspection is essential. This advice also applies to other construction machinery.

Beyond evaluating external features like dented panels or paintwork, it’s crucial to delve into the technical details. For the engine, check the exhaust pattern, oil condition, coolant, and blow-by rate. A visual inspection of the boom and stick is straightforward, but a specialist should measure the play in the slewing ring to assess wear.

One critical component is the hydraulic pump, whose performance can be evaluated through a specialized test. Ensure the hydraulic oil is at operating temperature before testing. Supplement this with measurements of the main pump pressure and control pressure. Additionally, inspect the hydraulic cylinders for internal leaks and check the travel motors and final drives. Using a professional inspection checklist will help ensure no component is overlooked.

What to Do if the Machine is Too Far Away

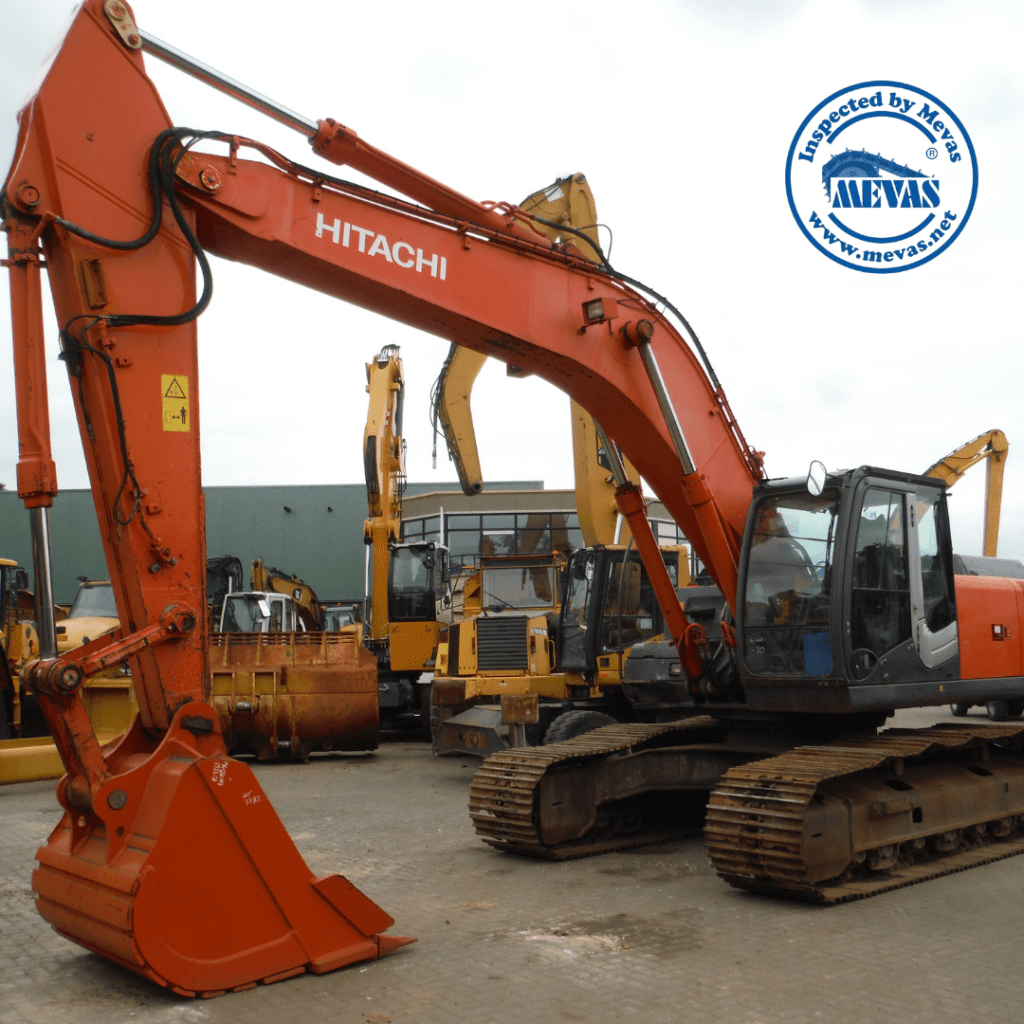

Regional inspection services are available in many countries, though they can be slow, costly, and not always specialized in construction machinery. MEVAS offers a more efficient solution with their international and professional construction machinery inspection services.

Professional Construction Machinery Inspection Service

MEVAS inspectors are available for Ritchie Bros. or P&E auctions in Dubai (U.A.E.), Caorso (Italy), Moerdijk (Netherlands), and many other locations. The team, based in Germany, provides inspections across all European countries, with inspectors even available in China and Chile.

Verifying Excavator Working Hours

While an inspection reveals the current state of an excavator, understanding its history can be invaluable. Specialized companies like MEVAS can download data from the internal computer of some machines. If this isn’t possible, there are often other ways to investigate the machine’s history.

What can the machine’s oil tell us?

If you know the service life of the engine oil or hydraulic oil, an analysis of the oil components can tell a story. Too much silicon in the oil indicates external contamination. Too much copper or chromium tells us something about the wear in the hydraulic pump and the hydraulic cylinders. Soot in the engine oil provides information about the condition of the engine. And how much does the analysis cost? You can have an in-depth analysis carried out in a certified laboratory for as little as $120 per oil. Ask MEVAS for more details.

Digging even deeper?

For an in-depth analysis of the machine, you can even open the axle drives and look for chips on the magnetic drain plugs. The swing and boom lift cycle times can be compared to factory specifications. Even the engine blow-by effect can be measured.

How Much Does an Excavator Inspection Cost?

The cost of an inspection includes the travel and labor of the inspector. However, in our experience, an inspection is less expensive than repairing a hydraulic cylinder. It all depends on the location of the machine, the size of the excavator and the extent of the inspection required.

A comprehensive inspection report can help you negotiate the price of any necessary repairs to the machine. So it often pays for itself. And make sure you are not being cheated when buying used machinery.