Haga inspeccionar las máquinas antes de compro, Shanghai, Hefei, Anhui

¿Ha encontrado máquinas de construcción usadas en China que desea comprar? ¿Quizás en Shanghái o Hefei? Podemos ofrecerle inspecciones básicas de máquinas usadas en Shanghái, Anhui y en la zona de Hefei. »» Il existe une version de cette page en français. »» There is an english version of this advise.

Tarifa de inspección

Debido a los gastos de desplazamiento y comunicación, se aplican los siguientes costes por los servicios de inspección en China. Tenga en cuenta que viajar a Hefei y Anhui es muy largo. Por este motivo, la tarifa es relativamente alta.

- Una máquina en la zona de Shanghái 880 euros (1000 US$) (posible con tarjeta de crédito)

- Máquinas adicionales en el mismo lugar 350 euros (400 US$)

- Inspección de una máquina en la zona de Hefei o Anhui 1500 euros (posible con tarjeta de crédito)

- Máquinas adicionales en el mismo lugar, Hefei o Anhui: 350 euros (420 US$).

- Envío o inspección de carga de contenedores en Shanghái: 800 euros (900 US$).

Ámbito de nuestras inspecciones de maquinaria en China

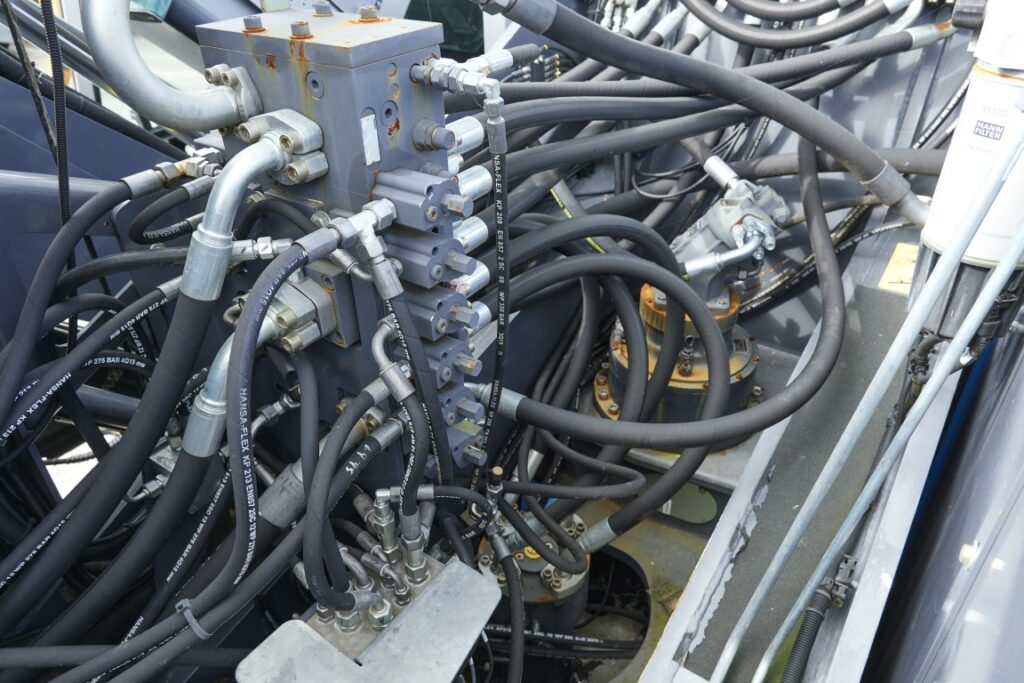

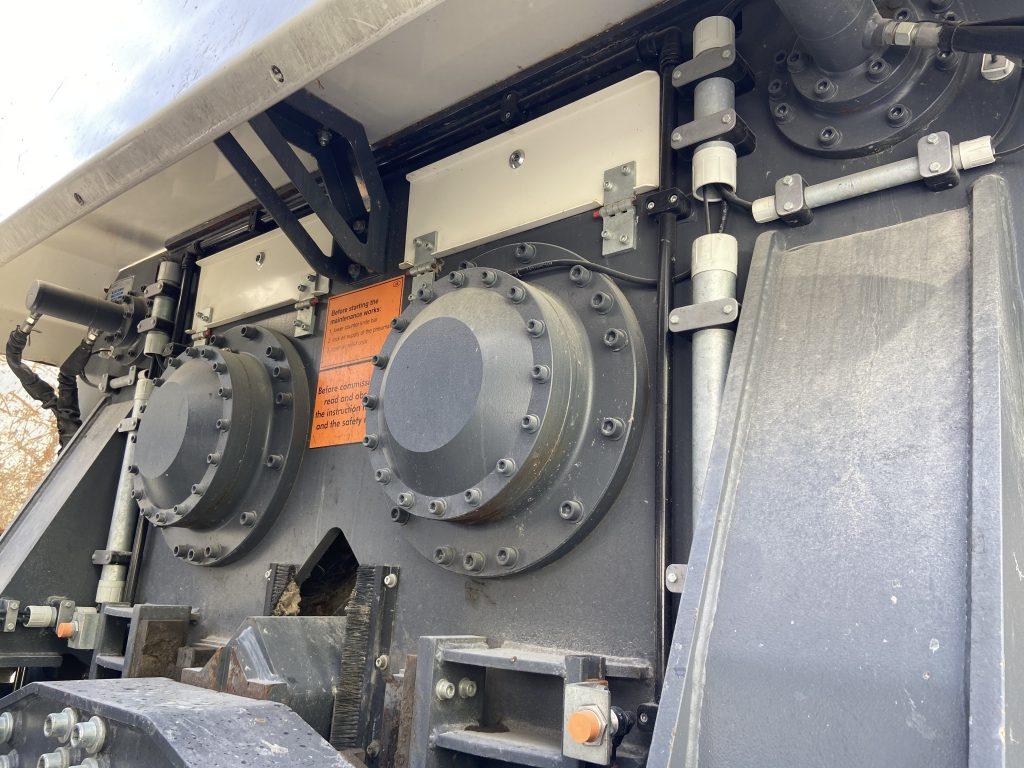

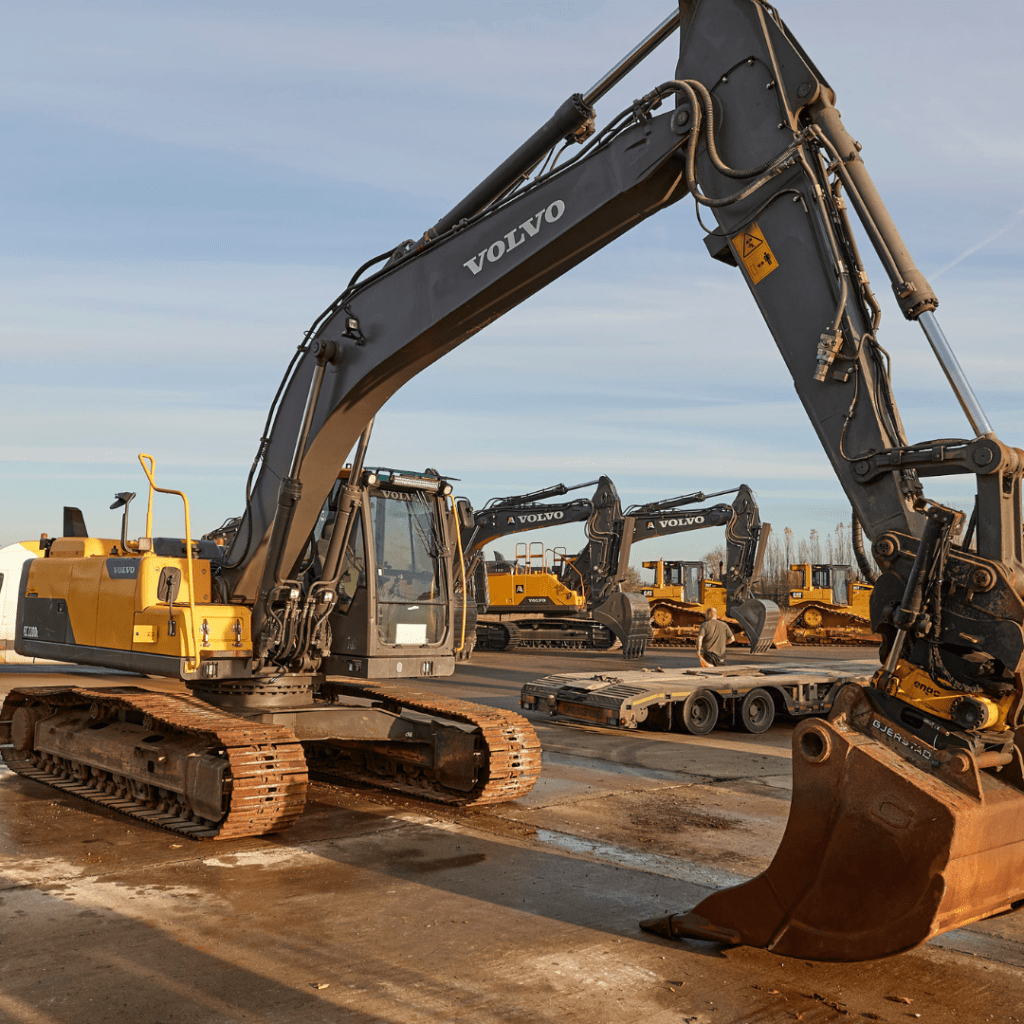

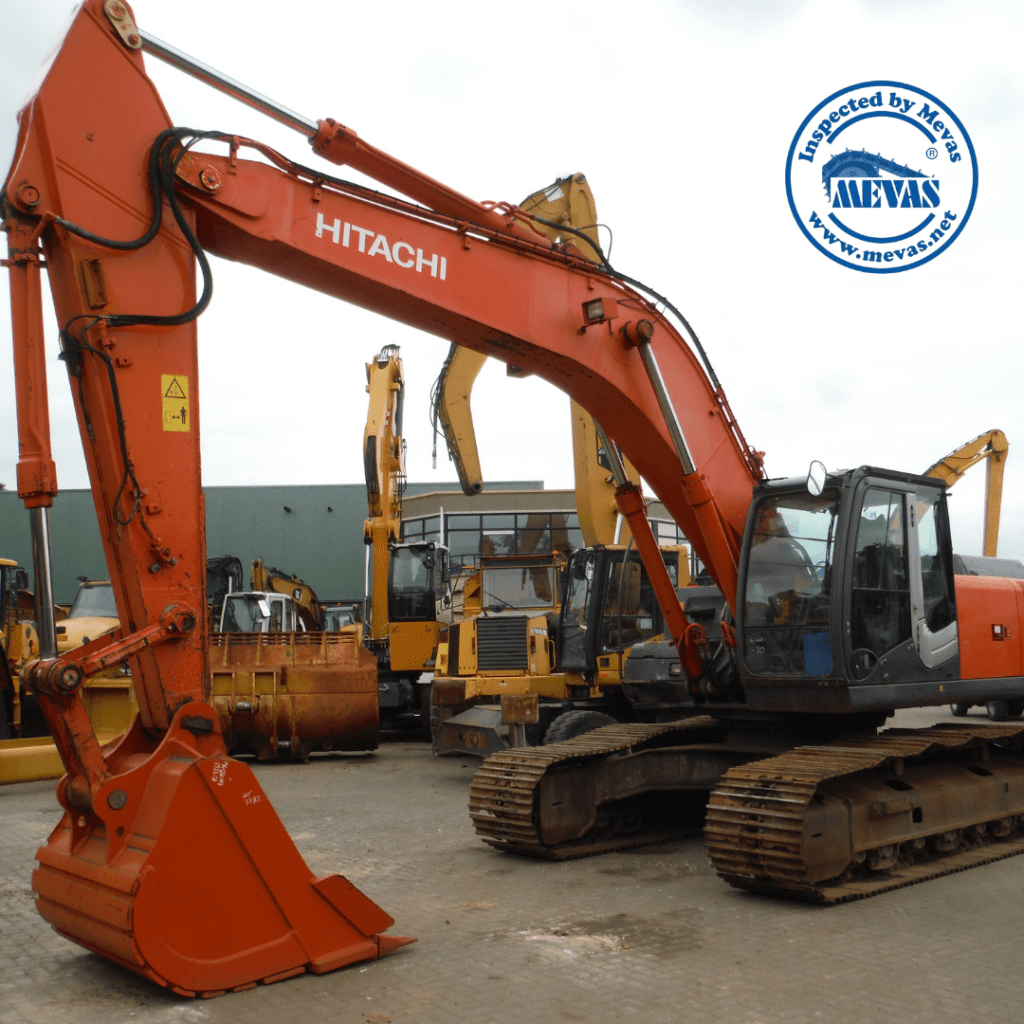

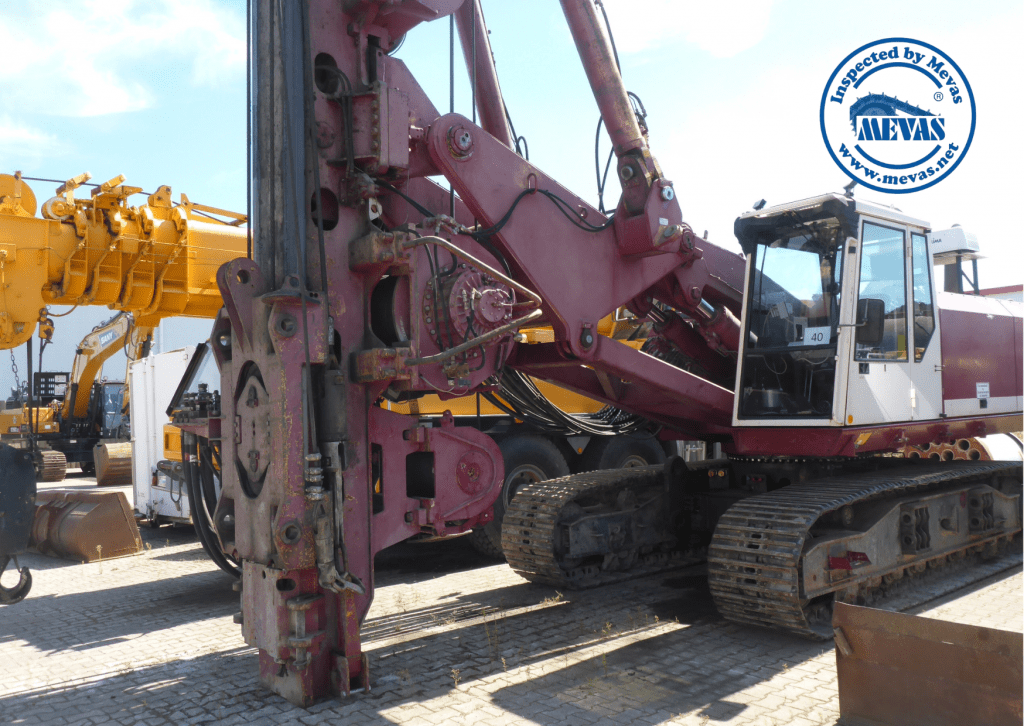

Nuestro servicio en China incluye una inspección visual de la máquina, con una prueba de funcionamiento realizada por el conductor del vendedor. Nuestro inspector toma varias fotografías y vídeos, y comprueba visualmente el estado y el desgaste de la máquina, incluidos los números de serie y los motores. También busca fugas y grietas en el chasis, evalúa los accesorios y los neumáticos, y realiza una valoración de la fiabilidad del vendedor. Aunque no se trata de una inspección técnica perfecta, puede ayudarle a evitar los errores más importantes a la hora de comprar una máquina en China. Hemos tenido algunas sorpresas desagradables en Shanghái y sus alrededores, y algunos de nuestros clientes han perdido mucho dinero. Algunos incluso acabaron con una máquina diferente a la que habían inspeccionado. Por tanto, recomendamos encarecidamente realizar una segunda inspección en el puerto antes del envío para asegurarse de lo que está comprando. Inspeccionamos todas las marcas, como Caterpillar, Tadano, Komatsu o Doosan.

Equipos usados de Shanghái

Shanghái es conocida por tener una gran cantidad de máquinas de construcción interesantes, como excavadoras, palas cargadoras, rodillos, motoniveladoras y otras máquinas para la construcción de carreteras. Sin embargo, en China no se puede confiar ciegamente en los vendedores, ya que es habitual que las máquinas chinas se repinten y se vuelvan a etiquetar, lo que dificulta identificar el país de origen real. Esto puede suponer una desagradable sorpresa para los compradores cuando la máquina llega a otro país y no se dispone de piezas de repuesto. Para evitarlo, es muy recomendable que haga inspeccionar la maquinaria de construcción usada en China antes de su envío. Es especialmente importante no realizar ningún pago por adelantado hasta que esté seguro del estado y el país de origen de la máquina.

Inspección de carga en el puerto de Shanghái

Si desea un servicio adicional de inspección de carga en el puerto de Shanghái, también se lo podemos ofrecer. Debe comunicarse con el vendedor y las autoridades para que nuestro inspector pueda acceder al puerto. Por la inspección de carga se aplica una tarifa de 800 euros (900 dólares) por un servicio de un día.

Control de calidad de la maquinaria en Hefei o Anhui

Si ha encontrado una máquina en condiciones razonables y a buen precio en Anhui o Hefei, podemos enviar a un inspector. Debido al coste del desplazamiento en un país tan grande como China, no será un servicio barato. El inspector tendrá que viajar en avión o en tren de alta velocidad y pasar la noche allí.

Documentos, carga de contenedores y logística

No aprobamos documentos, no emitimos documentos de exportación y no nos encargamos de la logística dentro de China ni del envío desde este país. Tampoco podemos ayudar con la carga de máquinas en contenedores. Para obtener estos servicios, póngase en contacto con un agente de transporte o un taller local.

Verificación del número de serie

Para que se apruebe un número de serie, es muy recomendable ponerse en contacto con su distribuidor local de la marca correspondiente, como CAT o Komatsu. ¡No se fíe de las fotos o confirmaciones enviadas desde China!