Which is the appropriate crusher for my application?

Listen here to the full article

There are three main types of crushing plants which are used both in quarrying and in the recycling of building materials. These plants are differentiated according to the type of crushing tools. There are jaw crushers, impact crushers and cone crushers. In addition to these plants, we also know roller crushers, but these are not very common. The choice of system depends on the raw material. Is the system to process stone extracted from the quarry or is it for recycling building materials? Of course, the desired material to be produced during processing also plays an important role. Last but not least the expected capacity plays a significant role. All types of crushers have advantages and disadvantages. The costs for wear and tear are the most important parameter. PDF

Buying used instead new?

New and modern crushing plants have many advantages. Overload protection, oversize grain recirculation, hydraulic gap adjustment and low-emission engines are state of the art. However, these plants come at a price. Good quality used machines are a good alternative.

Where to find good quality equipment?

Ideally, you should have a dealer in your home country where you can view and test a system. The dealer will often also provide good advice on whether the system is the right one for the task at hand. He will advise you on whether the feed material, the expected result when crushing and the capacity of the plant are suitable for your tasks.

However, due to the limited number of available systems, you often have to search far and wide. Most used machines are listed in the common databases for used heavy machinery. A wide selection of those websites is available at www.used-equipment.de. And regardless of whether the system is purchased near or far, it makes sense to send a mechanic to inspect it who also understands this technology.

Buying directly from contractor?

Buying from an entrepreneur often seems attractive because of the significantly lower price. You can perhaps also expect a more honest description of the crushing plant and the experience with it. However, this should only be done at home. When buying from abroad, problems quickly arise that the contractor is unable to solve. This starts with the handling of VAT and does not end with the export documents.

How to inspect a used crusher?

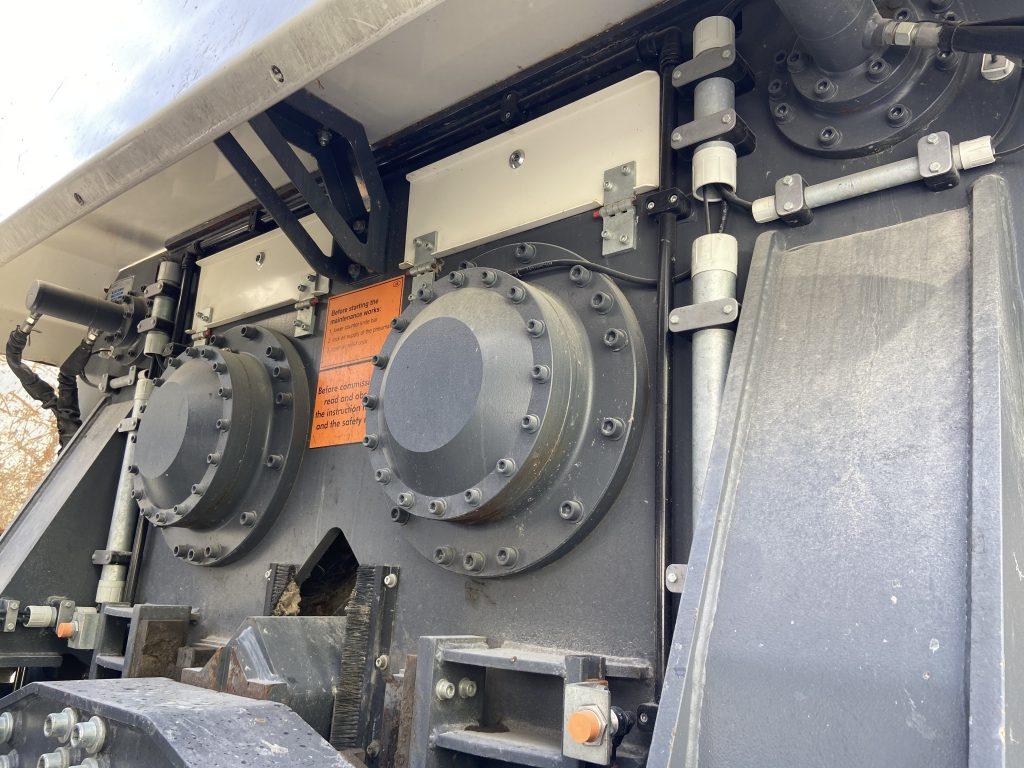

During the operation of crushing plants, enormous forces are exerted due to the weight of the material. Shocks and vibrations play an important role. And the plants are usually exposed to high levels of dust. The intensity of this stress has a major impact on the wear and service life of components. Experienced engineers from the recycling plant sector know the weak points and know where to take a closer look.

You should always use a checklist for the respective type of system so that you do not overlook any assemblies. Professional inspection companies such as Mevas can read out the engine data for many systems. The oils used can also be analysed. Each system has specific assemblies and the technician should be familiar with these and know how they ideally work. This allows the remaining service life and problems to be interpreted.

Cost for using a professional Mevas inspector

Mevas has inspectors for all types of heavy equipment. In 25 countries, local inspectors can assist with a professional inspection for crushers and screens as well as other construction and mining equipment. The final price for an inspection depends very much on the location of the machines, the scope of the inspection and the size of the equipment. Typically, the fee starts at €800 for a single piece of equipment. The inspector records a video and many images during operation and compiles a detailed report based on a 60-point checklist for the crusher inspection. Get in touch with Mevas for a quotation now.

Download the article for free as a PDF.