Is there an inspection service available for used concrete pumps and ready-mix trucks?

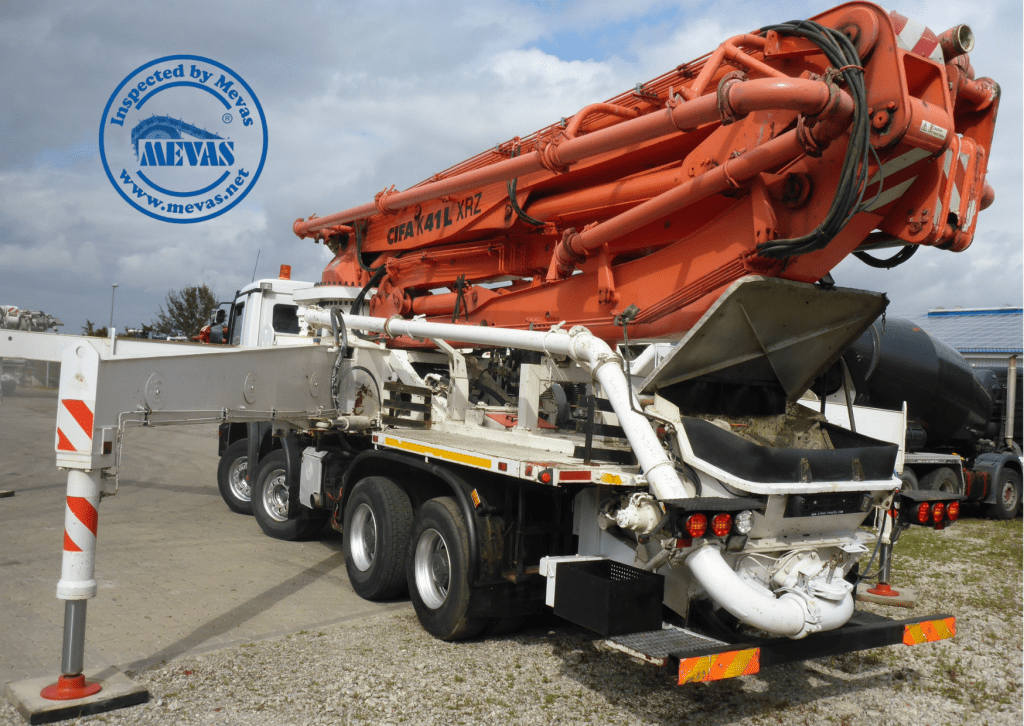

At MEVAS, we take the guesswork out of your used concrete equipment purchases. Our team of seasoned engineers specializes in pre-delivery inspections, ensuring that your investment is a sound one.

What sets us apart? ✅ Comprehensive Visual Checks: Our experienced engineers meticulously inspect every component, leaving no stone unturned. ✅ Rigorous Functional Testing: We don’t just look; we put the equipment to the test, including a water test, to verify its operational integrity. ✅ Detailed Inspection Reports: Within just one day, you’ll receive a comprehensive inspection report, complete with high-quality photos and a video. It’s like having eyes on the ground even when you can’t be there. ✅ Confidence in Your Purchase: Our reports provide a clear picture of the equipment’s condition. You’ll know if it’s in excellent shape, requires minor touch-ups, or needs significant repairs.

MEVAS is your trusted partner in making informed decisions when buying used concrete pumps, ready-mix trucks, and batching plants. Choose confidence, choose MEVAS.”

What kind of concrete equipment exists and can be inspected by Mevas technicians?

Concrete production and transport equipment plays a crucial role in the construction industry, ensuring that concrete is mixed, transported, and placed efficiently and effectively. There are various types of equipment used in the concrete production and transport process, including:

- Batching Plant: Batching plants are facilities where raw materials like cement, aggregates, and water are mixed to produce concrete. There are two main types: ready-mix concrete plants and central mix concrete plants.

- Transit Mixers: These are specialized trucks designed to transport freshly mixed concrete from the batching plant to the construction site. They have a rotating drum to keep the concrete from setting during transportation.

- Concrete Pumps: Concrete pumps are used to deliver concrete to high-rise or hard-to-reach construction sites. They come in two main types: boom pumps, which use a robotic arm to place the concrete accurately, and line pumps, which use hoses to pump concrete to the desired location.

- Agitators: These are similar to transit mixers but are used to transport ready-mixed concrete over shorter distances. They don’t have the rotating drum and are primarily used for onsite concrete delivery.

- Mobile Mixers: Mobile mixers are portable concrete mixing units that can be transported to the construction site. They are typically used for smaller projects or in locations where a stationary batching plant is not practical.

- Concrete Buggies: Concrete buggies, also known as power buggies or Georgia buggies, are motorized vehicles used to transport and pour concrete in areas with limited access.

- Concrete Conveyor Belts: Conveyor belts are used to transport concrete from the mixing plant or mixer to the pouring location. They can be mounted on trucks or used as standalone units.

- Concrete Buckets: These are used to transport and pour concrete in small quantities. They are often attached to cranes or other lifting equipment.

- Slipform Pavers: Slipform pavers are specialized machines used for the continuous pouring and shaping of concrete, typically for road construction and large-scale paving projects.

- Concrete Reclaimer Systems: These systems are used to collect and recycle excess or returned concrete, reducing waste and environmental impact.

- Concrete Mixers: Concrete mixers come in various sizes and configurations, including portable and stationary mixers, which are used for smaller-scale on-site mixing.

- Volumetric Mixers: Volumetric mixers are mobile batching plants that can mix concrete on-site to specific proportions, allowing for flexibility in the concrete mix design.

- Concrete Silos: These are storage structures used to store bulk quantities of cement and other materials before they are mixed in the batching plant.

- Concrete Cooling Systems: In hot climates, concrete cooling equipment is used to control the temperature of the concrete during mixing and transportation to prevent premature setting.

- Concrete Aggregates Crushers and Screens: Equipment for crushing and screening aggregates used in concrete production.

The choice of equipment depends on the scale of the project, the distance to the construction site, and other project-specific requirements. Proper selection and maintenance of concrete production and transport equipment are essential for ensuring the quality and efficiency of concrete construction.