Inspecție la nivel mondial a tuturor tipurilor de utilaje pentru construcții

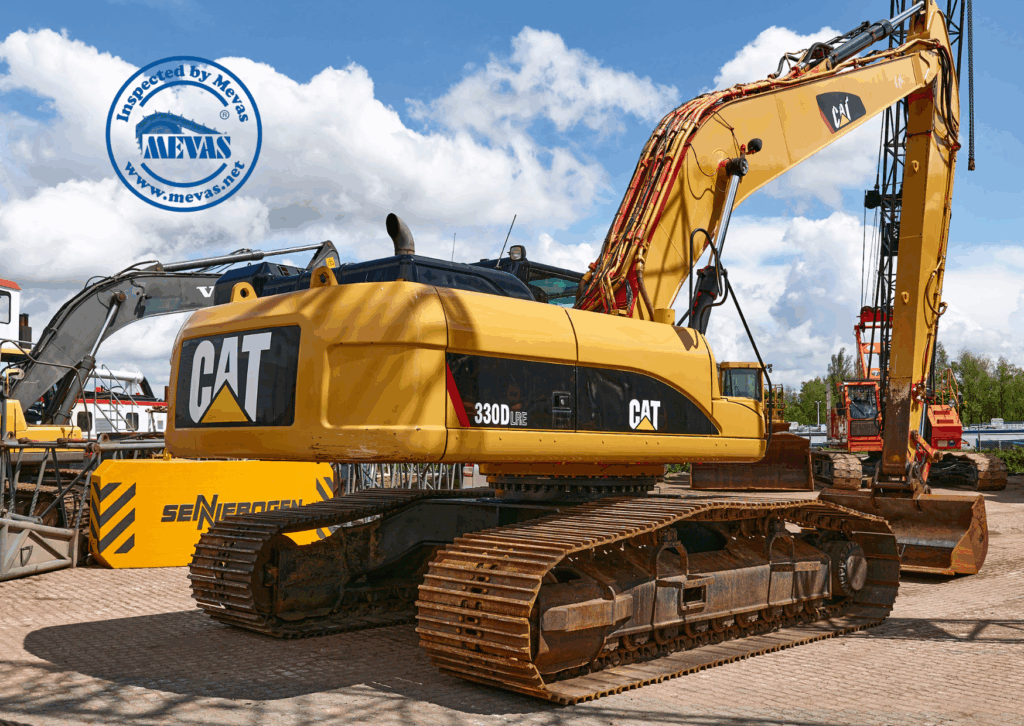

MEVAS este o companie germană specializată în inspecția și evaluarea utilajelor grele. Cu o rețea mondială de tehnicieni experimentați, mergem direct la fața locului pentru a vă ajuta să luați decizia corectă atunci când achiziționați utilaje de construcții, utilaje miniere sau camioane grele second-hand.

Inginerii noștri sunt special instruiți pentru a identifica problemele tehnice ascunse și pentru a evalua corect starea echipamentelor și a utilajelor de construcții înainte de achiziție.

Inspecții pentru utilaje de terasament

Experiența noastră acoperă toată gama de mașini de șantier.

Verificăm zilnic, în numele clienților internaționali:

- excavatoare pe șenile, excavatoare mobile

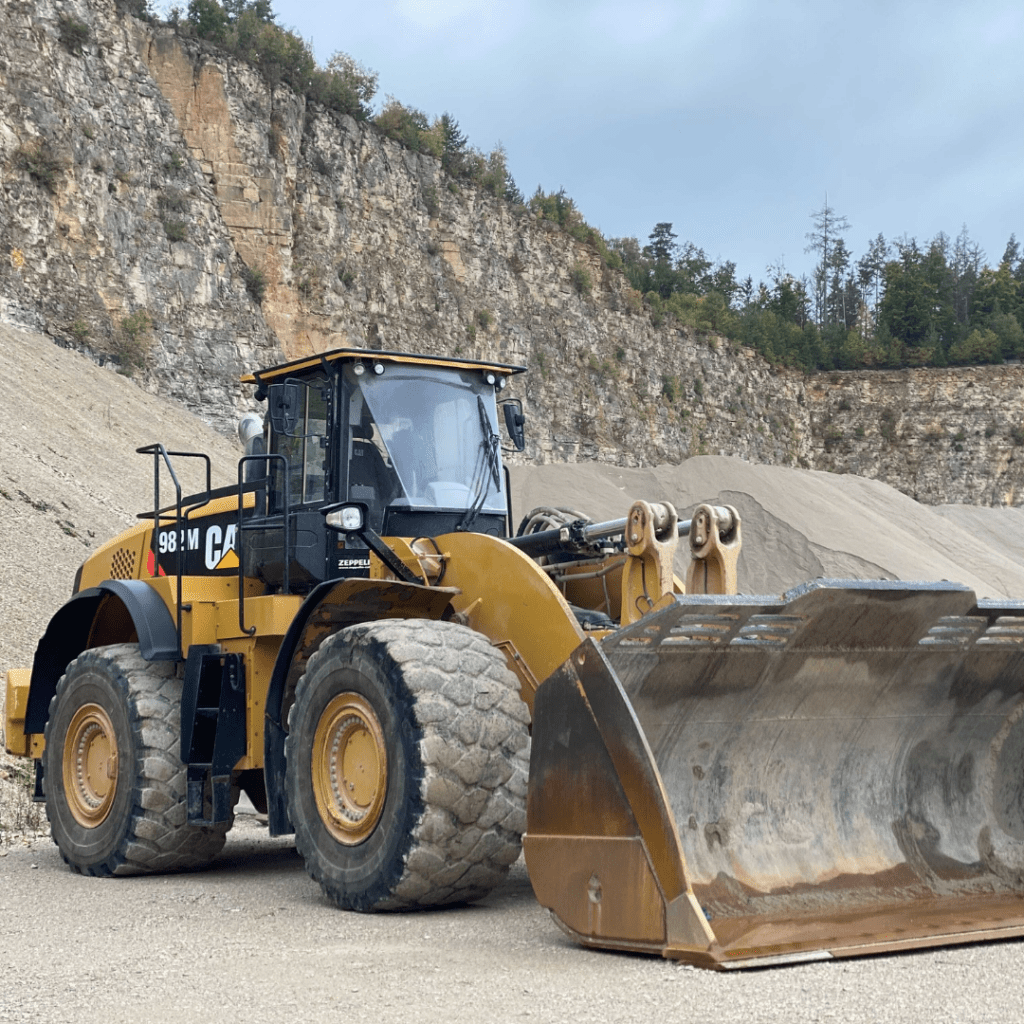

- încărcătoare cu cupă, încărcătoare pe șenile

- încărcătoare pe roți, motogreder

- alte utilaje pentru terasamente

Avantaje pentru clienți: identificăm uzura, problemele tehnice și riscurile ascunse înainte de a investi.

MEVAS are o pasiune pentru utilajele mari. Avem experiență în inspecția și testarea:

- Utilaje grele (Komatsu, Caterpillar)

- Echipamente de foraj pentru cariere și lucrări speciale de construcții

- Instalații de concasare și sortare

- Mașini pentru construcții rutiere

- Macarale mobile și macarale pe șenile

Elaborăm rapoarte detaliate pentru a ne asigura că echipamentele achiziționate de dvs. sunt gata de utilizare la capacitate maximă. Rapoartele noastre privind starea mașinilor sunt recunoscute la nivel internațional și respectă standarde tehnice înalte. starea mașinilor sunt recunoscute la nivel internațional și respectă standarde tehnice înalte.

Evaluarea valorii utilajelor pentru construcții

Echipa noastră experimentată întocmește rapoarte de evaluare a valorii actuale a utilajelor de construcții, utilajelor miniere și macaralelor. Nu contează unde se află utilajele. Putem oferi rapoarte de evaluare la fața locului sau online. Doriți să inspectați și să evaluați o flotă completă în vederea achiziționării sau vânzării? Noi putem face asta!

Serviciul de inspecție pentru macarale și echipamente de ridicare

Inginerii noștri au inspectat deja peste 600 de macarale în întreaga lume.

Acoperim:

- Macarale mobile (ATT)

- Macarale pe șenile

- Macarale montate pe camion

- Macarale rutiere

- Reach stackers pentru containere

- Stivuitoare mari cu furcă

Avantaj pentru clienți: rapoarte obiective și transparente înainte de a cumpăra echipamente scumpe.

De ce să alegeți MEVAS?

- Rețea globală de inspectori independenți

- Experiență vastă cu utilaje de construcții, minerit și transport

- Rapoarte clare și profesionale, cu fotografii și documentație completă

- Ajutor în negocierea prețului, bazat pe starea tehnică reală

👉 MEVAS – Inspectorii de utilaje grele în care puteți avea încredere.

Nu suntem implicați în comerțul cu mașini și nu acceptăm comisioane de intermediere. Găsiți o selecție de portaluri pentru mașini second-hand pe pagina www.used-equipment.de.

Informații privind expertizele pentru utilaje de construcții în format PDF

Information about our services is also available in Indonesian, Polish, Chinese and Romanian language. There is a text in Slovenian, Albanian, Turkish, Croatian and Hungarian language. Even a post is available in Danish and Suomi (Finish) is present. Info in Czech, Greek and Arabic. Not to forget to mention the info min Hindi and Ukrainian. Our neighbors speak Dutch.