The first auctions of the year are just around the corner. So the question arises: Is it a good idea to buy machines there? And what needs to be considered? Buying used heavy equipment at an auction can be a good idea, but it comes with both advantages and risks.

The advantages are:

- Cost savings: Auctions often offer the opportunity to purchase equipment at a lower price than buying new.

- Choices: Auctions offer a wide range of equipment options, allowing you to choose between different makes, models and conditions. This can be an advantage when it comes to finding equipment that meets your specific needs.

- Potential for bargains: Occasionally you can find bargains or undervalued equipment at auctions, especially if there is less competition from other bidders.

But there are also risks that need to be considered:

- Do research first: Find out the market value of the equipment you are interested in so you can get a fair offer.

- Understand the auction terms and conditions: Familiarise yourself with the auction terms and conditions, including any buyer’s premiums or fees.

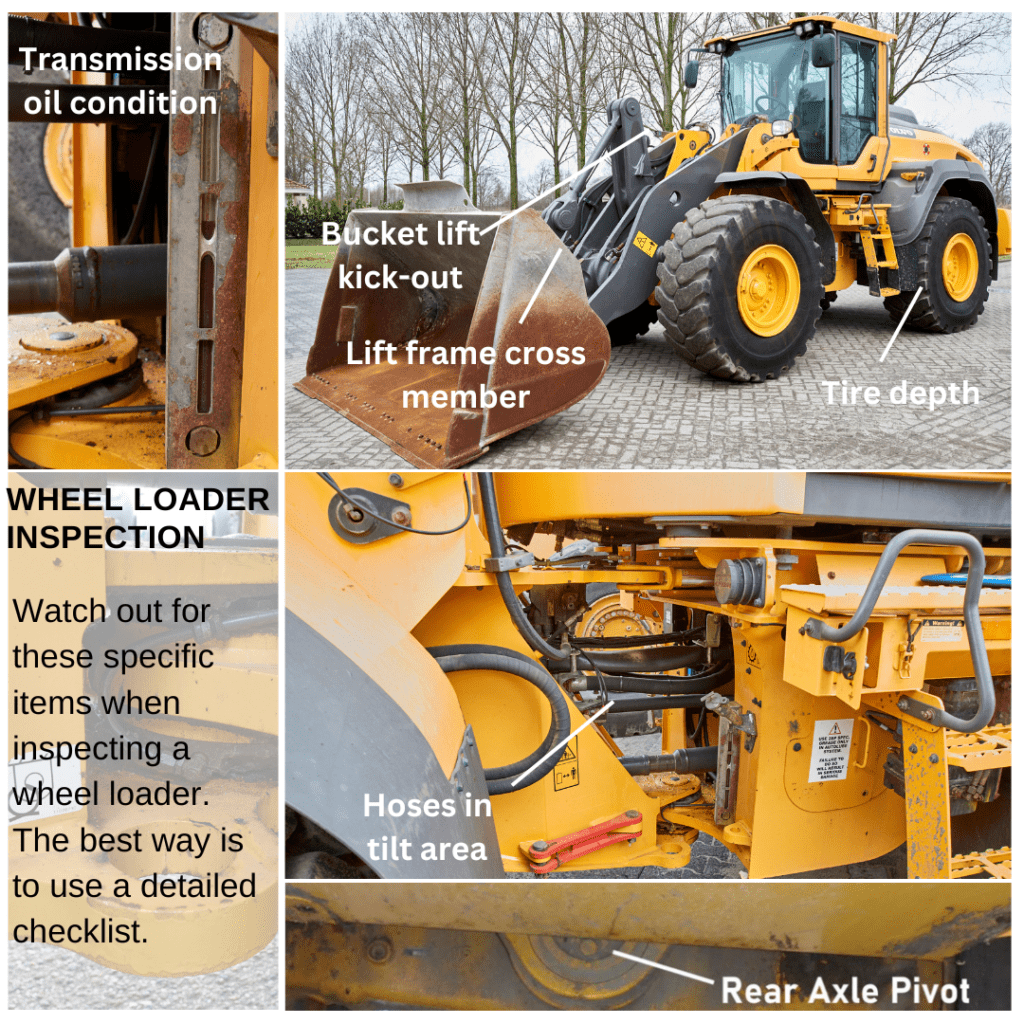

- Do a pre-inspection of the equipment: If possible, inspect the equipment before the auction. If you are to far away ask an expert. Mevas-Technicians can help you. Drop a message here.

Reminder: Set a budget and stick to it. This will prevent you from getting bogged down and investing more than planned.

Heavy Equipment Auctions

Euroauctions Leeds, GBR starts on Wednesday January 24, 2024 and RB auction Maltby, GBR starts on Wednesday Feburary 14, 2024. Mevas inspectors are available for on-site inspections for both auctions. If you need an independent machinery expert for unbiased inspection get in touch. We are www.mevas.co.uk and we are present in the United Kingdom with local inspectors.

We have created an overview of all other dates for heavy machinery inspections in Europe. This is constantly updated and can be accessed here. Our technicians are also available for auctions in Germany, Dormagen, The Netherlands, Moerdijk and many other locations.

Shorter inspections for auctions

On auction sites, it is often not possible or practical to carry out the full scope of a TA1-plus inspection. On the one hand, the possibility to operate machines is often limited. On the other hand, it does not always make sense to pay for a full inspection for a large number of machines, as the chance of becoming the highest bidder is limited. Therefore, we offer shorter inspections at a lower price. The final fee depends on where the auction takes place and how many machines someone wants to have inspected.

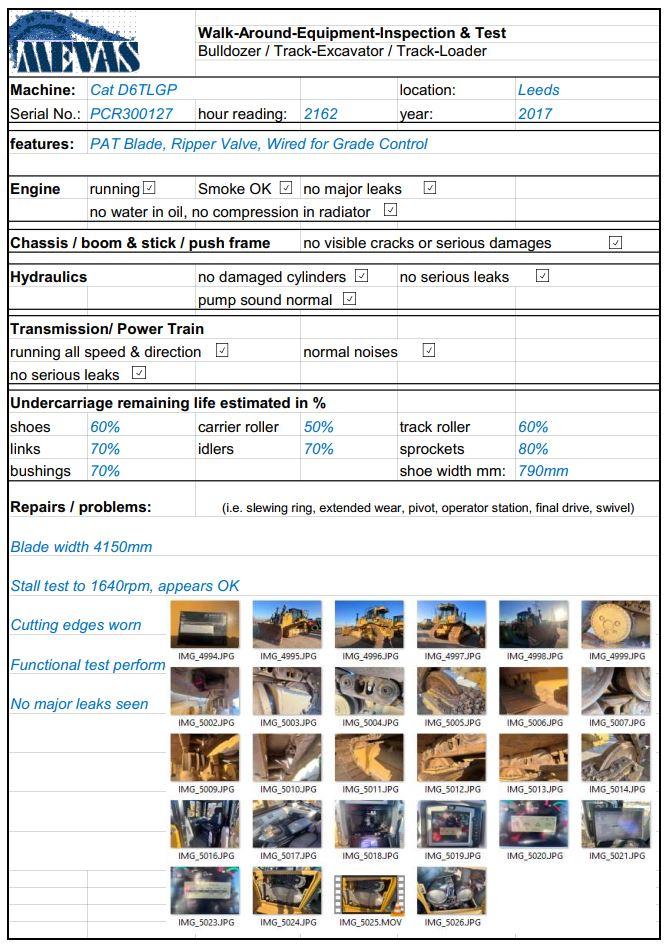

Sample reports for auction-site inspection

Below sample shows how a shortened inspection report looks like. Here you can download a PDF-sample.