Have you found used construction machines in China that you want to buy? Perhaps in Shanghai of Hefei? We can offer you basic inspections of used machines in Shanghai, Anhui and in the Hefei area. »» Il existe une version de cette page en français. »» Lee este artículo en español.

Inspection fee

Due the travel cost and the communication efforts the below cost applies for inspection services in China. Please note: To Hefei and Anhui it is a very long travel. Therefore the fee is comparably high.

- One machine in Shanghai area 880 Euro (1.000US$) (possible by Credit Card)

- Additional machines in same place 350 Euro (400 US$)

- One machine inspection in Hefei or Anhui area 1.500 Euro (poss. by Credit Card)

- Additional machines in same place Hefei or Anhui 350 Euro (420 US$)

Scope of our machinery inspections in China

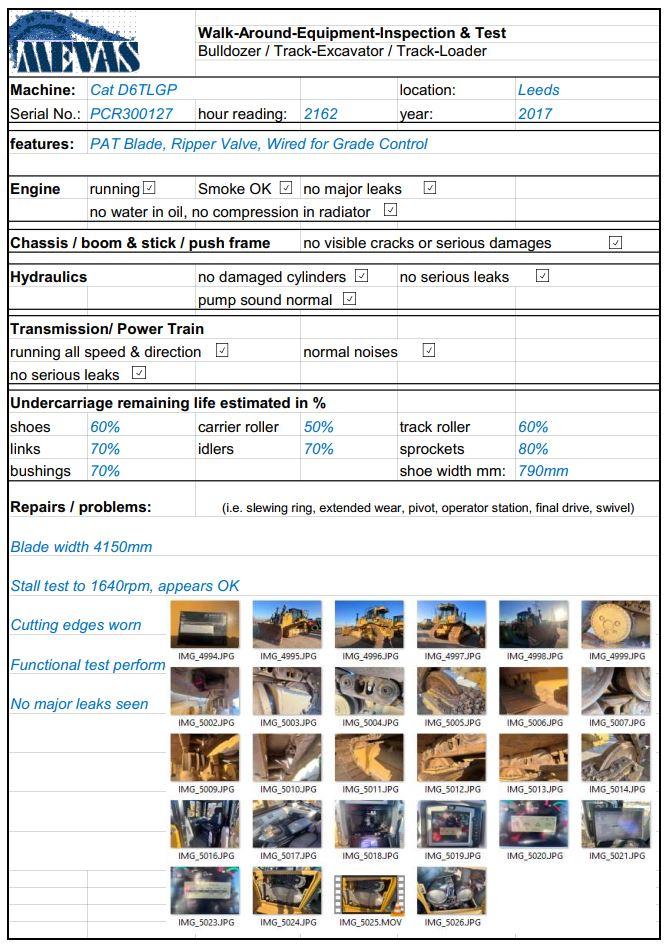

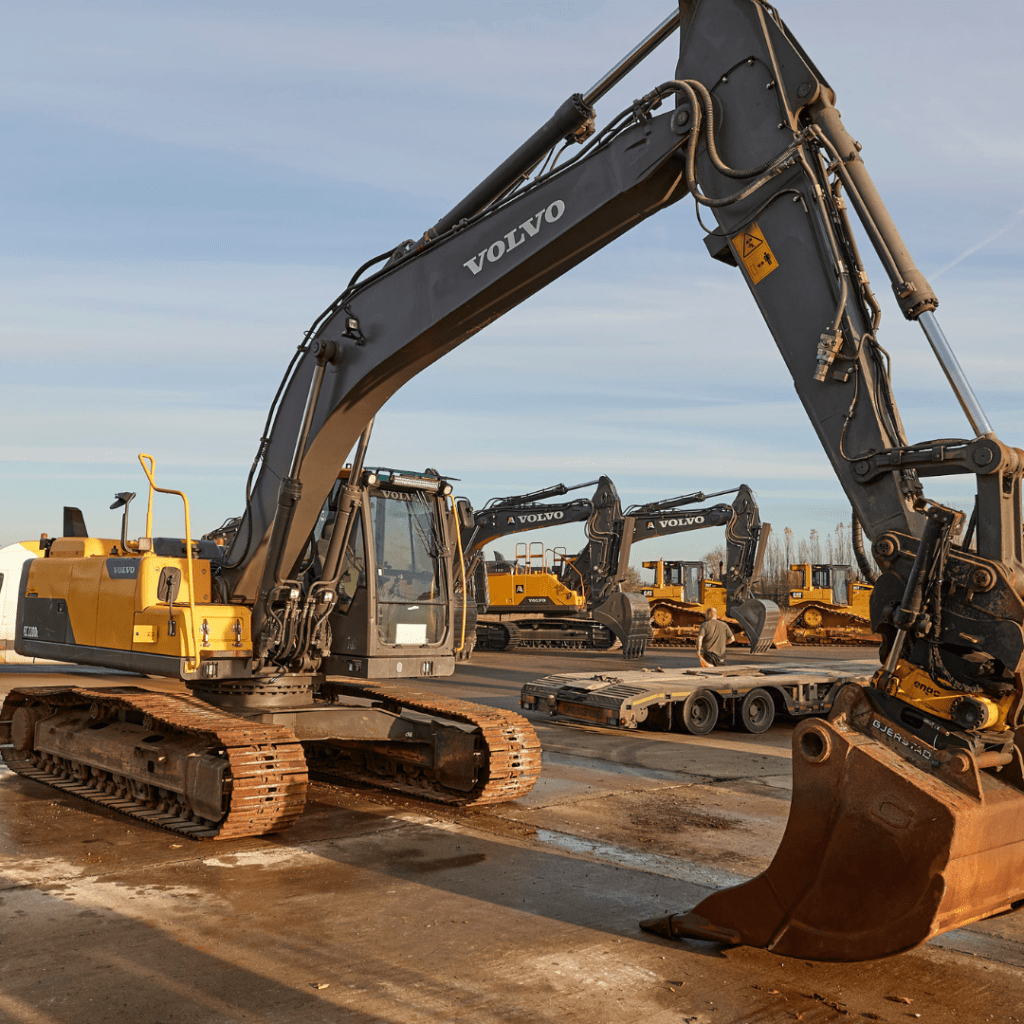

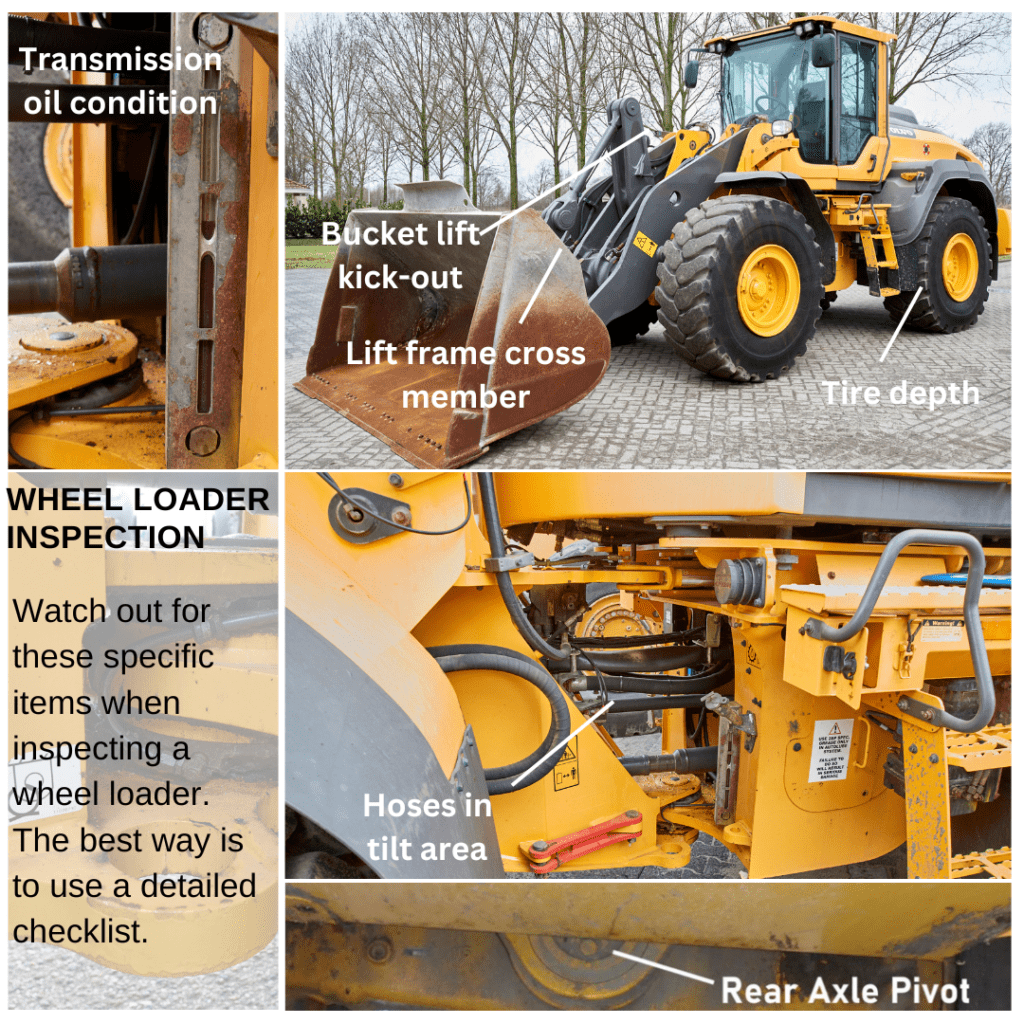

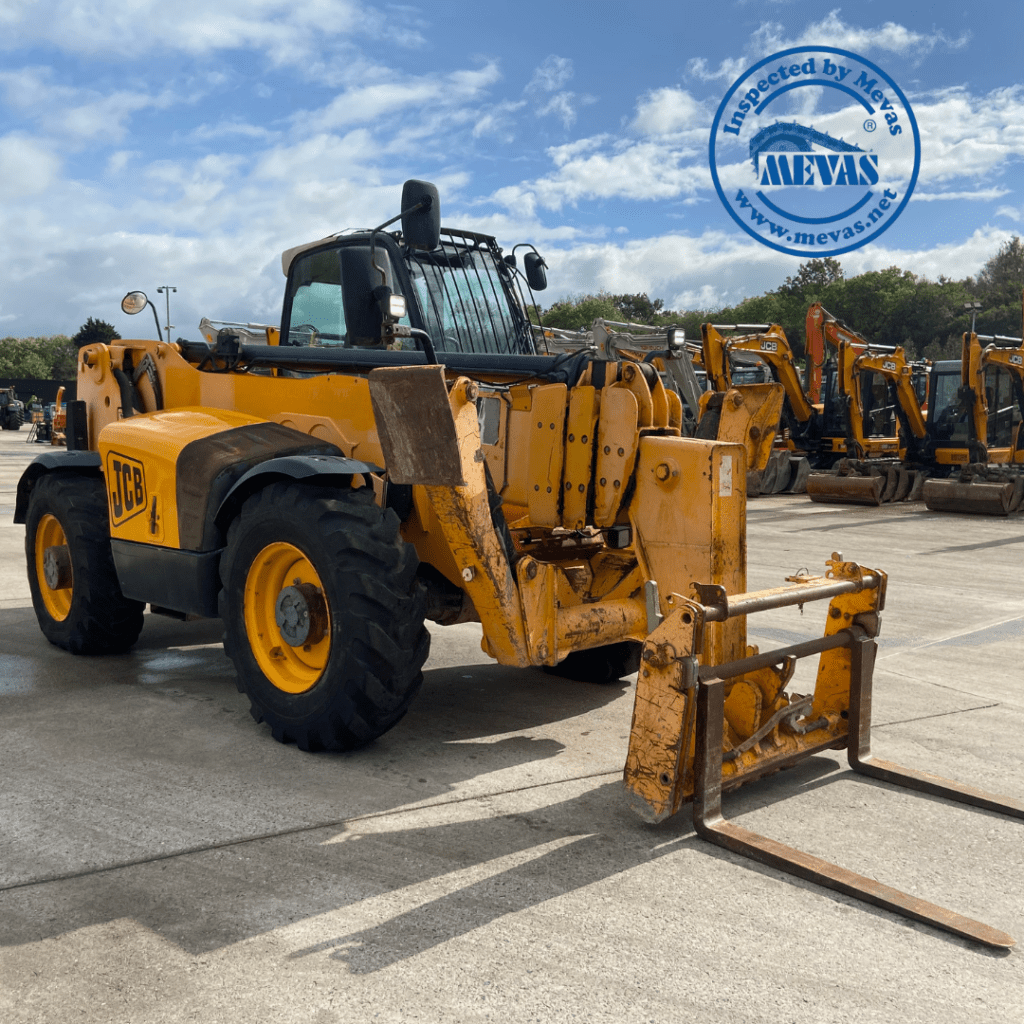

Our service in China includes a visual inspection of the machine with a functional test using the seller’s driver. Our inspector takes various photos and videos and visually checks the condition and wear of the machine, including the serial numbers and engines. He also looks for leaks and cracks on the chassis, assess the attachments and tires, and make an assessment of the reliability of the seller.

Sample reports for our inspection can be seen here.

While this may not be a perfect technical inspection service, it can help you avoid the biggest mistakes when buying a machine in China. We have had some unpleasant surprises in Shanghai and its surrounding areas, and some of our customers have lost a lot of money there. Some even ended up with a different machine than the one they inspected. Therefore, we highly recommend a second inspection at the port before shipment to be sure of what you are buying. We inspect all brands such as Caterpillar, Tadano, Komatsu or Doosan.

Used Equipment from Shanghai

Shanghai is known for having a lot of interesting construction machines like excavators, wheel loaders, rollers, motor graders, and other road construction machines. However, in China, you cannot blindly trust sellers as it is common for Chinese machines to be repainted and re-labelled, making it hard to identify the actual country of origin. This can be an unpleasant surprise for buyers when the machine arrives in another country and spare parts are unavailable. To avoid this, it is highly recommended that you have used construction machinery inspected in China before shipment. It is especially important not to make any down payments until you are sure about the condition and country of origin of the machine.

Loading Survey in the port of Shanghai

If you wish an additional service of a loading survey in the port of Shanghai this can be offered as well. You need to communicate with the seller and the authorities to grant access to port for our inspector. For a loading survey a fee of 800 Euro (900$) applies for a one-day service.

Quality Control of machinery in Hefei or Anhui

If you found a machine in reasonable codition and for a good price in Anhui or Hefei we can send an inspector. Due to the travel cost in the big country China it will not be a cheap service. The inspector needs to travel by plane or high-speed train and he needs to stay overnight.

Documents, container stuffing and logistics

We do not offer approval of documents, we do not offer any export documents and we don’t take care for logisticts inside China or Shipping from China. We are also not in a position to support with stuffing machines into containers. Please contact a shipping agent or a local workshop for those services.

Serial Number Verification

To get a serial number approved it is highly recommended to contact your local dealer of the related brand such as CAT or Komatsu. Don’t rely on pictures or confirmations sent from China!