Support for Construction and Heavy Equipment Procurement

An inspection company such as MEVAS can play a crucial role in supporting heavy equipment procurement by providing independent and professional evaluation of the equipment being considered for purchase. Here’s how our services can benefit the process:

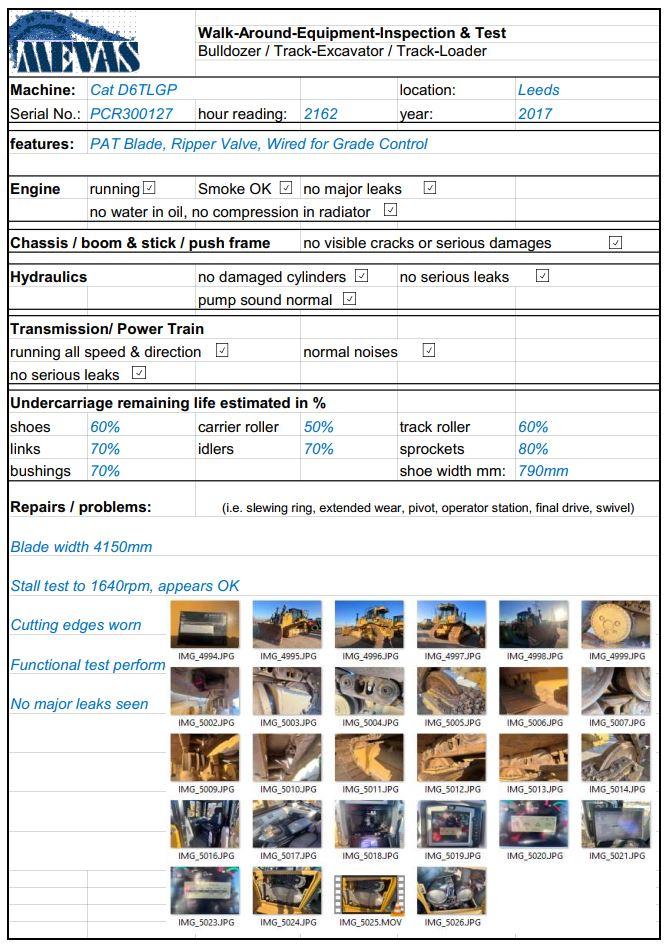

- Reduced Risk: Inspections help identify underlying issues with the equipment, such as hidden repairs, excessive wear and tear, or potential safety hazards. This knowledge empowers buyers to make informed decisions and avoid costly surprises after purchase.

- Improved Negotiation: A detailed inspection report provides leverage during negotiations with sellers. By highlighting any problems or needed repairs, buyers can use this information to justify a lower purchase price or request concessions from the seller.

- Ensuring Safety: Inspections pay particular attention to critical safety features of the equipment. Identifying potential safety hazards allows buyers to address them before the equipment is put to use, preventing accidents and injuries on the job site.

- Verification of Condition: An inspection verifies the condition of the equipment against the seller’s description or any provided service records. This helps ensure the buyer is getting what they are paying for and avoids any discrepancies.

- Peace of Mind: Having qualified inspectors evaluate the equipment provides peace of mind to the buyer. They can be confident they are making a sound investment in reliable machinery.

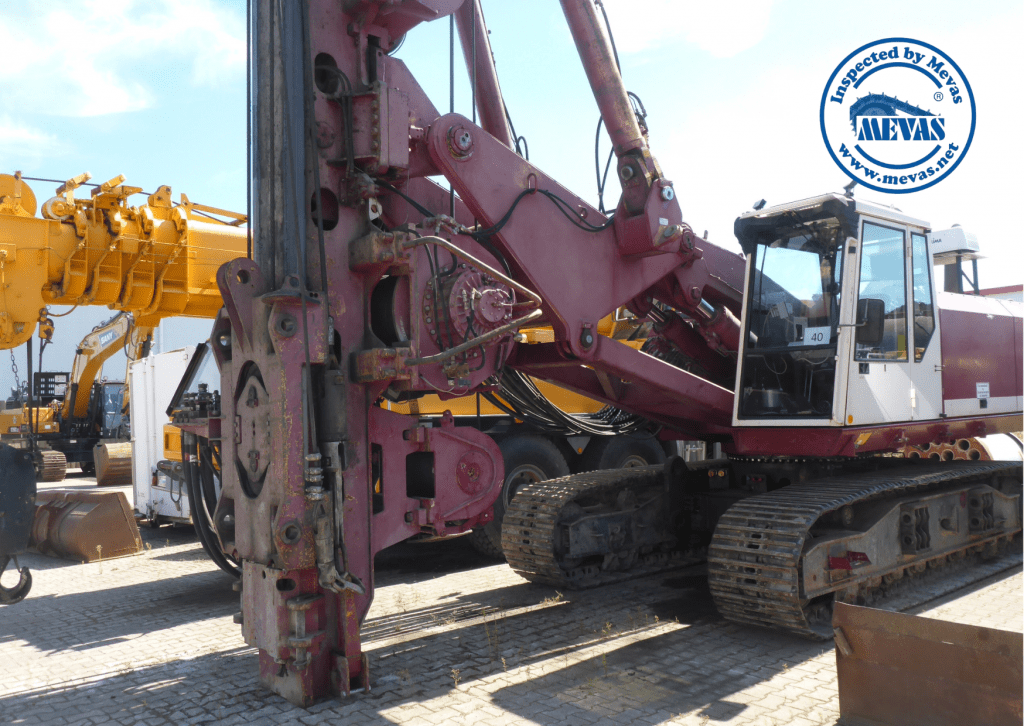

MEVAS can offer various services tailored to the specific needs of the procurement process, such as pre-purchase inspections, operational testing, and verification of compliance with safety regulations.

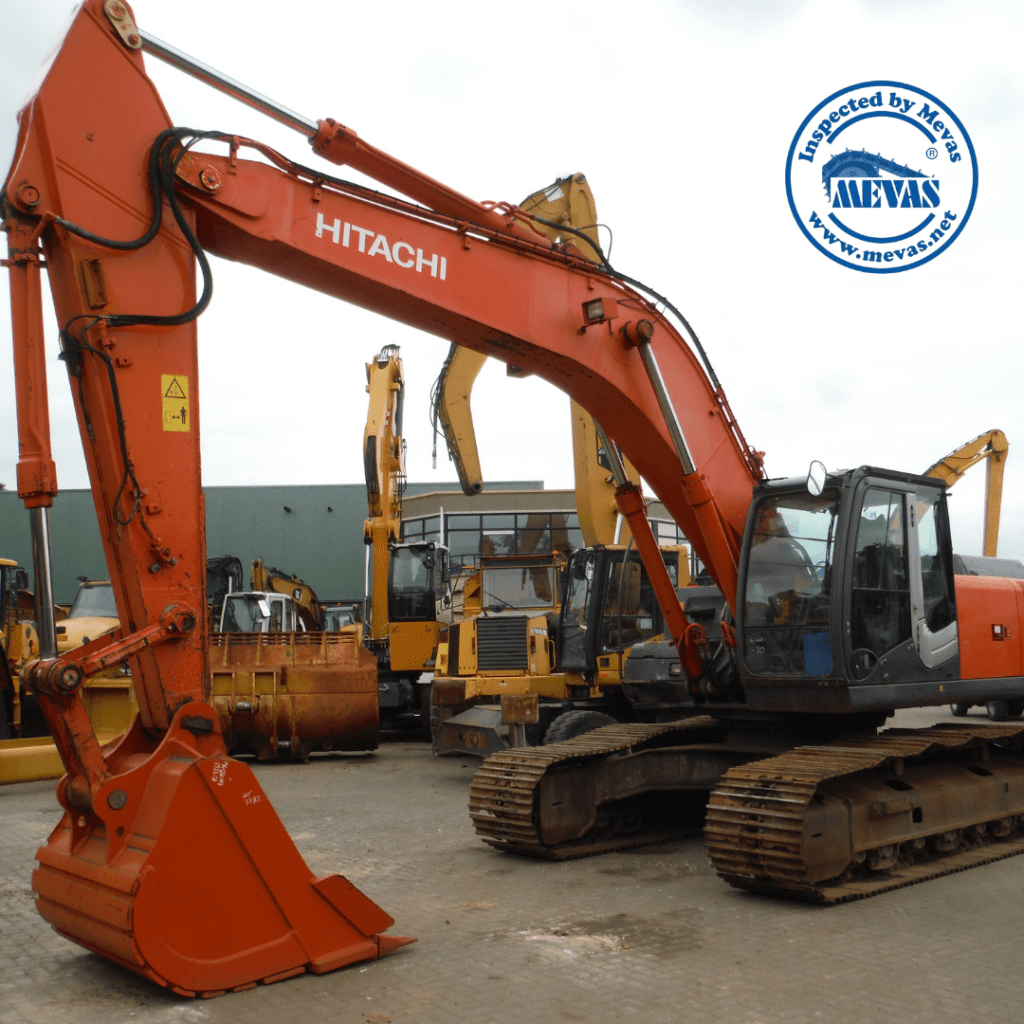

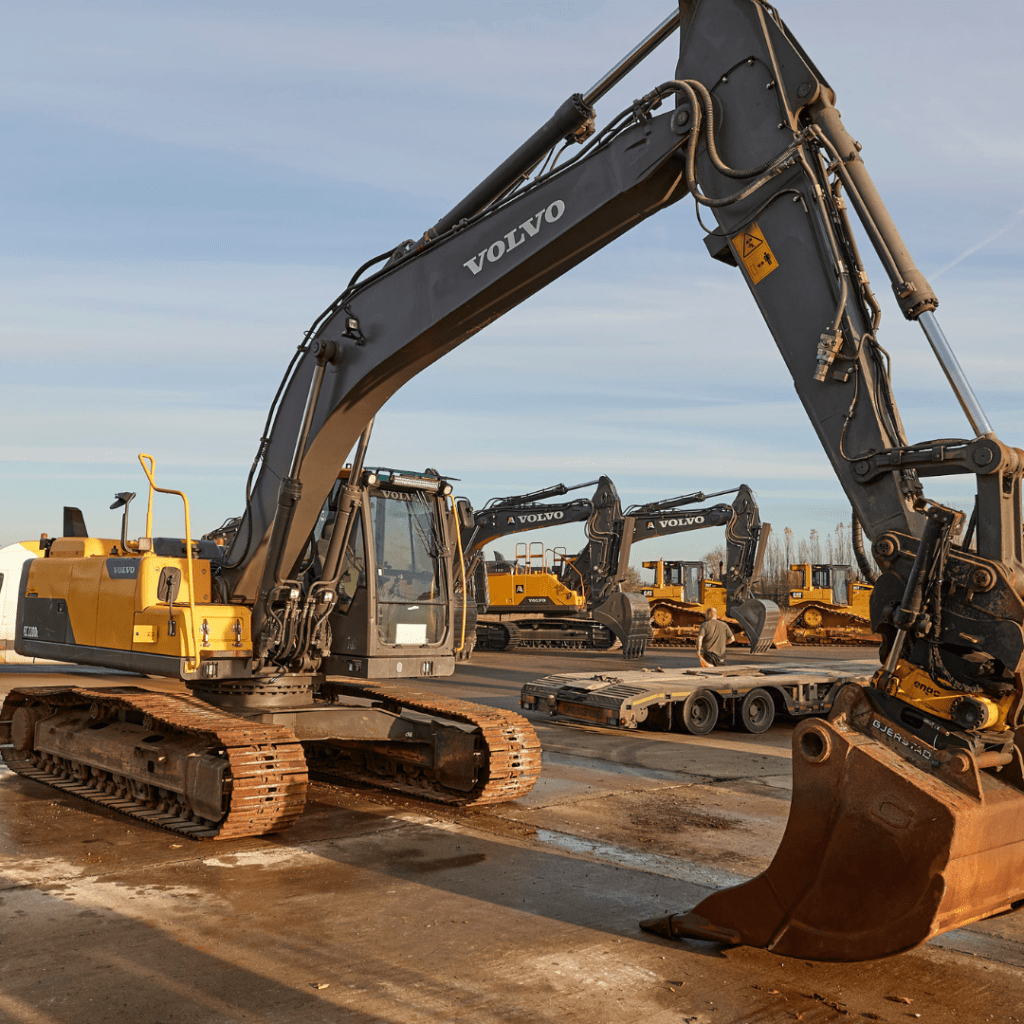

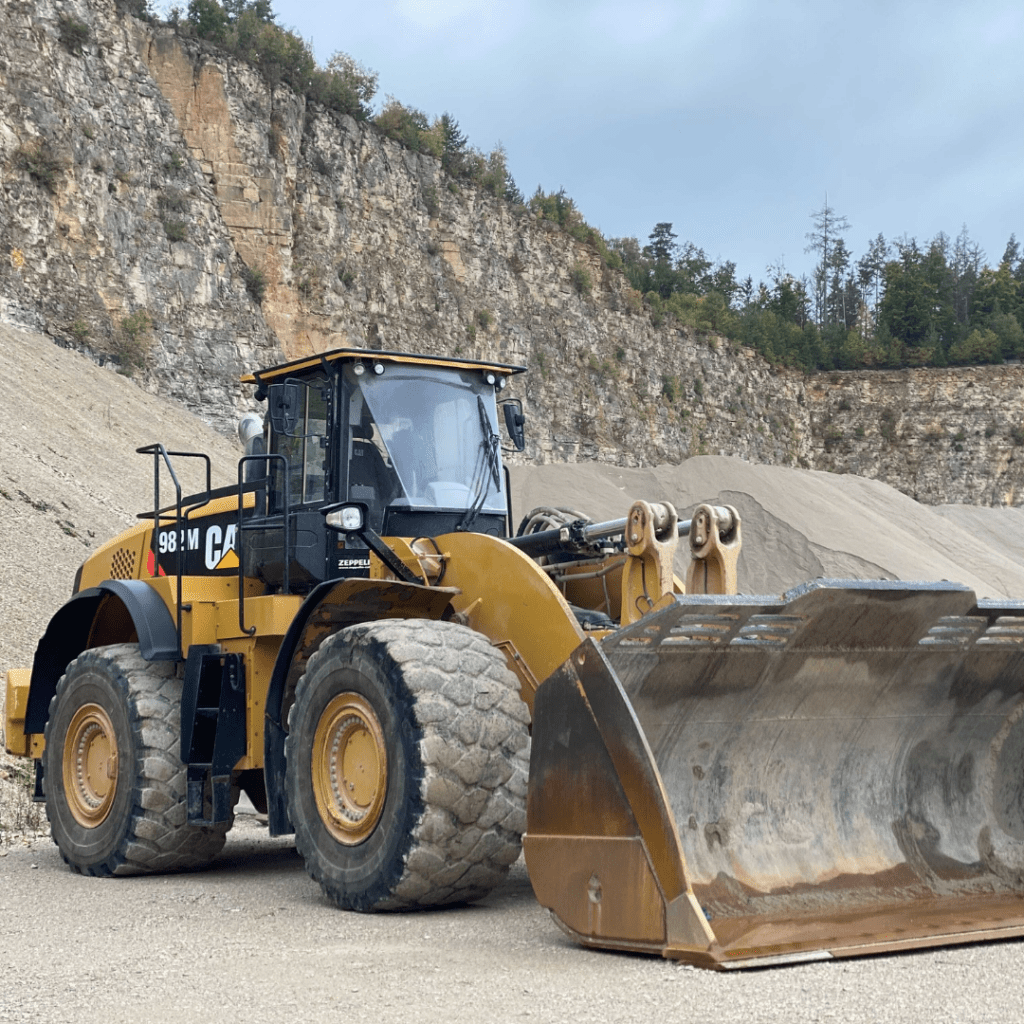

Specialized in mining machines and construction machinery

Mevas is operating as a valuation and inspection company for larger machines since 2006. Regardless of whether they are Komatsu dumpers, Volvo wheel loaders or Caterpillar bulldozers: We know our way around them. We can both check the technical condition and examine whether the price offered is reasonable. We have a proven track record in such tasks.

Heavy Machinery Trading support

We are your independent team for analyzing heavy machinery, cranes and trucks. Therefore we cannot offer you machines. Not even if you were to offer a commission. This ensures that our view of the true condition of the equipment is not clouded. Our service ensures that you find the most suitable equipment for your application needs or your customer. We are happy to help you find reliable suppliers.

What means Heavy Equipment Procurement?

Heavy equipment procurement is the process of acquiring the large machinery needed for industries like construction, mining, agriculture, and forestry. This involves identifying the specific equipment requirements, finding qualified suppliers, negotiating the best price and terms, and finally finalizing the purchase.

Here’s a breakdown of the typical heavy equipment procurement process:

- Identifying Needs: The first step involves understanding what kind of equipment is needed. This considers factors like project requirements, budget, and existing equipment inventory.

- Supplier Research: Once the needs are identified, potential suppliers who can provide the required equipment are researched. This may involve contacting manufacturers, distributors, or even used equipment sellers.

- Qualification and Selection: Suppliers are then evaluated based on factors like experience, reputation, pricing, and after-sales support. A shortlist of qualified suppliers is created for further negotiation.

- Negotiation and Contract: Negotiations with shortlisted suppliers are conducted to get the best possible price, financing terms, and delivery schedules. Once an agreement is reached, a formal contract is signed.

Obtaining heavy equipment can be a significant investment, so the procurement process aims to ensure efficient use of funds and the acquisition of equipment that meets the project’s needs.